Project Overview

Introduction

This client, a global leader in the production of aluminum and related products, has been shaping the industry for more than a century. At one of its most important U.S. sites, the organization faced the pressing challenge of preserving its legacy while driving performance improvements that could meet the demands of today’s competitive environment. The facility’s long history and community significance made it a critical proving ground for operational change.

Background

Founded more than a century ago, this facility was among the first aluminum smelting operations in the country, taking advantage of abundant natural resources and transportation links. Over the decades, it grew to become one of the largest employers in the region, driving both local economic growth and community development. For much of the 20th century, the plant represented stability, prosperity, and innovation.

Industrial Operations and Innovations

The facility specializes in primary aluminum production using industry-leading processes. Continuous investment in technological upgrades, including energy-efficient smelting and automation systems, helped it serve diverse industries such as automotive, aerospace, construction, and packaging.

Yet by the 21st century, global market pressures and rising energy costs created significant operational and financial challenges. Modernization efforts reduced emissions and improved efficiency, but the facility still faced declining output, workforce reductions, and the need for sharper operational discipline.

Performance Results

Read the Full Case Study Here

Operational Challenges

By the 21st century, the site encountered persistent challenges that constrained performance and profitability:

- Poor OEE and inconsistent schedule attainment.

- Limited use of time-based expectations and KPI discipline.

- Equipment downtime and reliability shortfalls.

- Inefficiencies with cold startups following maintenance shutdowns.

- Misaligned or underutilized Management Operating Systems (MOS).

- Inconsistent shift handoffs and weak communication practices.

- Delays driven by skill gaps and labor misallocation.

- Significant scrap, rework, and yield losses.

- Gaps in supervisor onboarding and role clarity.

- Underdeveloped accountability systems and uneven leadership effectiveness.

Collectively, these issues slowed output, inflated costs, and left frontline teams without the clarity and support required to consistently meet performance targets.

Why POWERS

To address these challenges, the POWERS team partnered with the client to deliver a structured improvement program centered on leadership, cross-functional collaboration, and operational discipline. The engagement focused on three primary levers of change:

- Customized Frontline Leadership Development

Through close collaboration, our on site leaders designed a tailored leadership program aimed at revising operational standards and embedding high-integrity business processes. This included the integration of effective existing tools and the creation of new frameworks to drive accountability and consistency across the organization. - Targeted Cross-Functional Improvements

Improvements were driven across Production, Maintenance, and Engineering functions. By unifying these areas with standardized KPIs and operational excellence methodologies, we ensured that rapid gains would be both measurable and sustainable. - Focused Operational Improvements

The engagement targeted measurable improvements in Cast Rod Throughput, Billet Cost per Labor Hour, Labor Utilization, and Sow Quality. These focus areas were selected to directly increase line availability, strengthen capacity utilization, and reduce downtime—all critical to restoring competitiveness and profitability.

Results

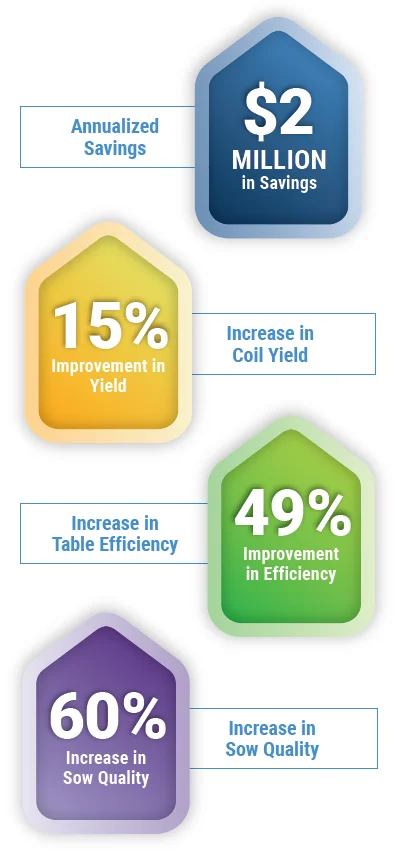

Within a concentrated sprint, the client achieved significant, measurable results:

Cast:

- $2.0M in Annualized Savings

- 15% increase in Coil Yield

- 49% increase in Table Efficiency

- 59% improvement in Bar Attainment

- 28% increase in Throughput

- 60% increase in Sow Quality

|

Testimonials

“Very open to questions and assistance in delivery to all aspects of Production. I would recommend their services throughout the company. And would like to thank them for my development.”

“I have learned to be more involved with my team through having short interval follow ups, and have learned to escalate situations more when it is needed”

“I believe in the short time with Powers, the tools put in place for Supervisors makes sustainability very achievable. Following a tried and true process, has shown me much improved results just by following THE PROCESS.”

“Powers helped elevate our planning tool which produced a clearer picture on production and schedule attainment”