Project Overview

About the Client

The client is a leading Tier 1 automotive supplier specializing in precision metal components, assemblies, and integrated systems for major vehicle manufacturers. Their vertically integrated operations span design, tooling, stamping, welding, and final assembly, delivering high-performance solutions that support vehicle safety, quality, and efficiency.

With a strong commitment to continuous improvement and lean manufacturing principles, the organization sought to enhance changeover performance and strengthen shift ownership as part of its broader initiative to elevate overall equipment effectiveness and plant-wide productivity.

Engagement Focus

The engagement targeted the need for faster, more consistent changeovers, an area identified as a major opportunity to recover capacity and improve throughput. The objectives were clearly defined:

Performance Results

Read the Full Case Study Here

- Reduce changeover time through structured SMED (Single-Minute Exchange of Die) methodology and on-the-floor coaching.

- Build ownership and accountability among operators, die setters, and supervisors through data visibility and disciplined routines.

- Implement sustainable systems and visual management tools to reinforce standard work and maintain long-term performance consistency.

This approach ensured that improvements were not only achieved but also fully embedded into the client’s daily management systems.

Key Accomplishments

Throughout the engagement, the POWERS team collaborated closely to drive measurable improvements and operational discipline.

- Conducted detailed time studies and video analysis to distinguish internal versus external setup activities and identify true sources of waste.

- Designed and implemented foundational systems that created structure and accountability, including:

- Pre-Flight Changeover Checklist ensuring all materials, tools, and personnel are prepared before equipment stops.

- Parameter Verification and “No-Run Without Parameters” (NRWPS) process guaranteeing setups are validated and locked in prior to production.

- Changeover Audit Tool used to track compliance, sustain standard work, and identify targeted coaching opportunities.

- Die Staging Area Optimization, converting underutilized floor space into a dedicated, organized staging zone, eliminating more than 300 feet of unnecessary forklift travel per changeover.

- Fixture Tracking System with audit process to ensure fixtures are always locatable, properly labeled, and well maintained.

- Standardized Shift Handoff Protocol to ensure critical information, production status, and tooling readiness are consistently communicated across shifts.

- Downtime Escalation Matrix defining clear ownership and response expectations to minimize delays and reinforce accountability.

- Introduced visual management tools, including hour-by-hour boards, shadow board templates, changeover prioritization maps, and staffing visuals, to promote data-driven decision-making and sustain improvements on the shop floor.

These tools and systems created a more predictable, proactive production environment and fostered a culture of continuous improvement across all levels of the operation.

Measured Results

All performance outcomes were jointly validated using the client’s recorded production data in conjunction with POWERS’ DPS (Digital Production System) analytics platform:

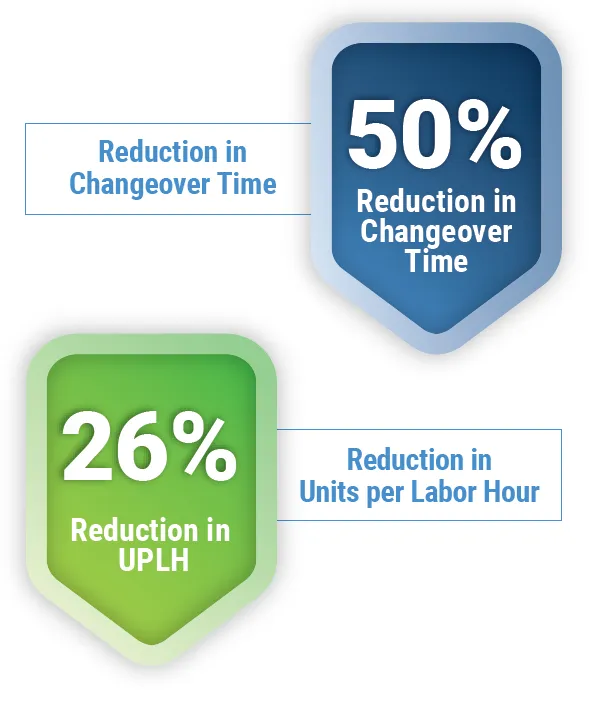

- Changeover Time: Reduced by 50%, from an 89-minute baseline to an average of 45.5 minutes across 66 documented events.

- Units per Labor Hour (UPLH): Improved by 26%, from 718 to 902, sustained over three consecutive weeks of data capture.

- Operational Readiness: Standardized equipment, tooling, and material staging processes have enabled predictable performance and reduced variability across shifts.

- Cultural Impact: Greater engagement and ownership from operators, stronger communication between leads and supervisors, and a shared understanding of performance expectations at each stage of the changeover.

Beyond the immediate metrics, the engagement established a replicable playbook for future improvement initiatives, setting a new standard for efficiency and accountability across the facility.

Sustainment Plan / Next Steps

To maintain progress and institutionalize the gains achieved, the following next steps were established:

- Finalize and deploy line boards and shadow boards across all production areas.

- Continue weekly Changeover Audits for each shift, reviewed by Stamping and Plant leadership to track adherence, trends, and opportunities for coaching.

- Reinforce Pre-Flight Checklists and Parameter Verification as mandatory standard work to ensure ongoing readiness.

- Sustain operator and lead coaching on changeover readiness and problem-solving using data insights from hour-by-hour boards.

- Integrate Action Item Log reviews into Tier meetings to strengthen accountability, encourage collaboration, and ensure continuous improvement momentum.

Summary

Through focused coaching, structured systems, and the application of POWERS’ Digital Production System, the client achieved measurable and sustainable gains in performance and engagement. Changeovers are now faster, more consistent, and executed with clear accountability. By embedding standard work and visual management into daily operations, the team established a solid foundation for continued improvement and long-term operational excellence.