Faced with ever-soaring demand and sizzling commodities prices, our always-innovative meat processing industry client brought us in to address flagging performance and lean up production wherever possible. Our team helped align their culture with performance to deliver productivity increases while reducing labor costs.

Project Overview

Performance Results

Background

This industry-leading meat processing company has built a reputation as a dependable partner to thousands of meat buyers and producers worldwide. Over its decades in business, the company has committed to continuously improving its products and services and exceeding the expectations of what any meat company could offer its global partners.

This innovative and dynamic company is dedicated to consistently meeting its promises of quality, on-time delivery, superior customer service, and real value.

However, dealing with the persistently high demand and supply challenges that have impacted many businesses in the food sector particularly harshly has required this company to redouble its efforts to keep its brand promise and build its competitive advantage. As a result, this stalwart organization engaged our team to continue exceeding its partners’ expectations in these challenging market conditions.

Situation

During our discovery, the POWERS team uncovered opportunities to improve leadership behaviors and the systems and processes used to manage operational performance. For example, from a frontline leadership behaviors perspective, supervisors spent only 15% of their time performing their supervisory duties of actively coaching, guiding, directing, and engaging their direct report employees.

In addition, unclear roles and responsibilities led supervisors to spend as much as 32% of the day performing the work of their frontline employees instead of focusing on their supervisory tasks. This lack of alignment with supervisors’ expectations and daily job realities led to the acceptance of a culture built on continuous day-to-day firefighting with no relief in sight.

At the same time, our team discovered deficiencies in the Management Operating System (MOS) used across the organization to manage production. Due to a lack of an effective MOS, clearly defined roles and responsibilities, and training for frontline leadership, the plants were underperforming in capacity, yield, and overall productivity. Additionally, labor costs were increasing due to overtime.

Results

Overall, our client’s leadership team felt more well-rounded in their management skills and abilities and empowered to meet their daily and long-term goals. This alignment of existing values and purpose with the daily behaviors necessary to embody them and perform at peak levels, added tremendous strength to their company culture.

With a reinvigorated and readied leadership staff, and a more straightforward MOS providing a daily and long-range roadmap to success, our client realized significant gains in productivity. For example, on-time startups, which languished at 52% during our discovery period, jumped to a 91% average during our engagement, a 75% improvement. In addition, our client reduced labor costs by cutting overtime a whopping 17% over the course of the project.

But most significantly, our client’s vital throughput metric, pounds per labor hour, enjoyed an 8% improvement overall, helping build on their already-strong reputation and continue satisfying their customers.

This Stalwart Global Meat Processing Industry Leader Engaged POWERS to Lean Up Production While Beefing Up Performance

Faced with ever-soaring demand and sizzling commodities prices, our always-innovative client brought us in to address flagging performance and lean up production wherever possible. Our team helped align their culture with performance to deliver productivity increases while reducing labor costs.

Background

This industry-leading meat processing company has built a reputation as a dependable partner to thousands of meat buyers and producers worldwide. Over its decades in business, the company has committed to continuously improving its products and services and exceeding the expectations of what any meat company could offer its global partners.

This innovative and dynamic company is dedicated to consistently meeting its promises of quality, on-time delivery, superior customer service, and real value.

However, dealing with the persistently high demand and supply challenges that have impacted many businesses in the food sector particularly harshly has required this company to redouble its efforts to keep its brand promise and build its competitive advantage. As a result, this stalwart organization engaged our team to continue exceeding its partners’ expectations in these challenging market conditions.

Situation Analysis

During our discovery, the POWERS team uncovered opportunities to improve leadership behaviors and the systems and processes used to manage operational performance. For example, from a frontline leadership behaviors perspective, supervisors spent only 15% of their time performing their supervisory duties of actively coaching, guiding, directing, and engaging their direct report employees.

In addition, unclear roles and responsibilities led supervisors to spend as much as 32% of the day performing the work of their frontline employees instead of focusing on their supervisory tasks. This lack of alignment with supervisors’ expectations and daily job realities led to the acceptance of a culture built on continuous day-to-day firefighting with no relief in sight.

At the same time, our team discovered deficiencies in the Management Operating System (MOS) used across the organization to manage production. Due to a lack of an effective MOS, clearly defined roles and responsibilities, and training for frontline leadership, the plants were underperforming in capacity, yield, and overall productivity. Additionally, labor costs were increasing due to overtime.

Executive leadership recognized the need to change the organization’s culture to retain their excellent team of people, prevent burnout, improve working conditions, increase productivity, and exceed their partners’ expectations. And with commodities prices of the organization’s input products projected to increase, margins were tightening, adding pressure to lower costs across the enterprise.

Our Approach

To turn around performance, our team focused on building a more robust and definitive Management Operating System and training their already willing frontline leaders and workforce on the skills and behaviors necessary to reverse the chaotic environment that had developed over time. Our team worked extensively with managers and supervisors, providing hands-on training and guidance to develop their skills and teach the behaviors necessary to increase their daily and long-term success.

Through a more structured and definitive Management Operating System, our team helped clarify the roles and responsibilities of supervisors and the entire production process. With more clearly communicated and documented expectations, leads, supervisors, and managers could work up to the level of their positions more successfully.

This more robust MOS also allowed frontline leaders to be more focused on problem resolution and the strategic planning of labor and equipment to improve throughput and carry the organization into the future.

The Results

The frontline leaders and supervisors on this project felt they were able to understand and clearly communicate what was expected of them each day and how to perform to those standards. Overall, our client’s leadership team felt more well-rounded in their management skills and abilities and empowered to meet their daily and long-term goals. This alignment of existing values and purpose with the daily behaviors necessary to embody them and perform at peak levels, added tremendous strength to their company culture.

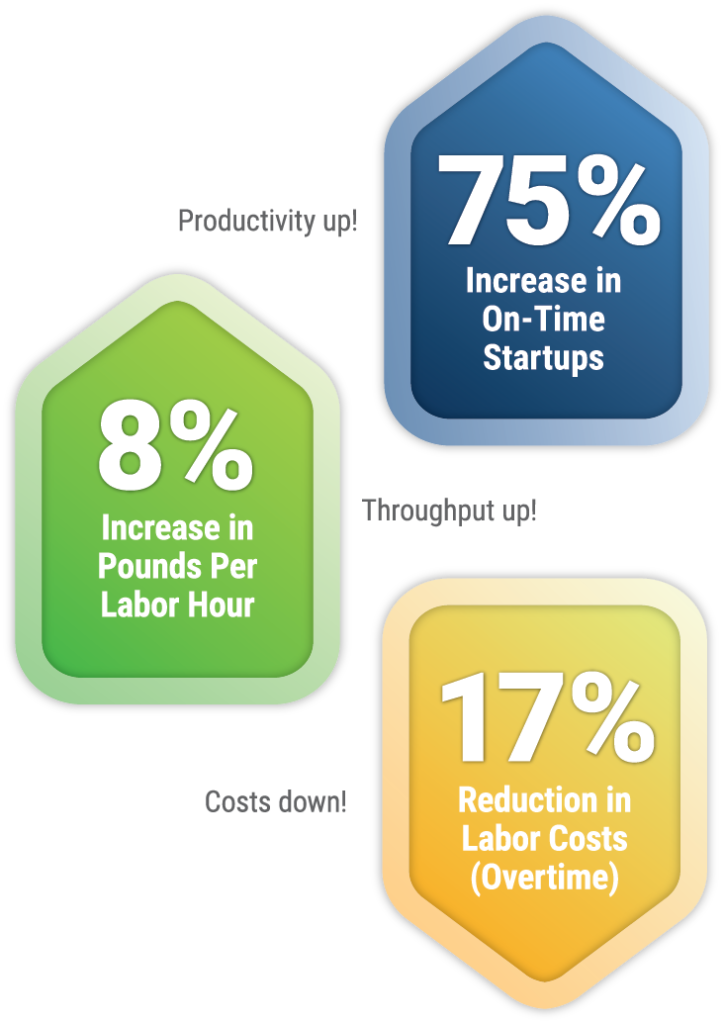

With a reinvigorated and readied leadership staff, and a more straightforward MOS providing a daily and long-range roadmap to success, our client realized significant gains in productivity. For example, on-time startups, which languished at 52% during our discovery period, jumped to a 91% average during our engagement, a 75% improvement. In addition, our client reduced labor costs by cutting overtime a whopping 17% over the course of the project.

But most significantly, our client’s vital throughput metric, pounds per labor hour, enjoyed an 8% improvement overall, helping build on their already-strong reputation and continue satisfying their customers.

Performance Results by the Numbers

- 75% improvement in on-time startups

- 8% increase in pounds per labor hour

- 17% reduction in overtime