Project Overview

The Situation

A leading global nutrition company faced a turbulent period at one of its major facilities two years before POWERS’ arrival. A wave of retirements and attrition stripped away decades of tribal knowledge. Processes like equipment startup and shutdown were undocumented, leaving inexperienced operators to figure things out on their own. Supervisors were new to leadership, without training or structured routines. A new plant manager was still learning how to lead the organization.

The result:

- Unstable operations – Overall Equipment Effectiveness (OEE) averaged just 71% for the previous 12-month period, far below the facility’s capacity.

- Unclear goals – Operators didn’t know the daily production target. Supervisors spent large parts of their day “available” but not adding value to their teams.

- Weak maintenance system – The CMMS was underutilized. Only 557 preventive maintenance tasks existed for 2,314 assets. Most maintenance was reactive, with technicians waiting for breakdowns instead of preventing them. Contractors filled gaps without accountability, and rework was common.

- Poor alignment – Leadership surveys showed over 90% of supervisors demonstrated marginal or unsatisfactory leadership practices. Supervisors reported events but did not manage capacity or performance…

Performance Results

Read the Full Case Study Here

- Cost of quality – Product quality claims averaged $232,000 per month for the previous 12-month period, far above leadership’s awareness. Customer complaints exceeded 90 annually, driving customer dissatisfaction.

- Market pressure – Product demand was rising, yet the facility was operating at just 71% of capacity. The gap meant lost revenue opportunities in a favorable market.

The plant was at risk: inconsistent throughput, costly rework, safety exposures, and leadership instability limited its ability to respond to growing demand.

The Analysis

POWERS’ diagnostic confirmed systemic issues:

- Goals and strategies were misaligned across leadership levels; only 19% of managers were fully aligned with top leadership priorities.

- Supervisors spent just 6% of their time actively supervising employees. Over 30% of their time was classified as “available,” meaning it created no value.

- Maintenance operated with a 70% break-in rate (emergency response work). Fewer than 50% of Work Orders were ever returned by technicians, and only 20% of those returned work orders contained usable detail, crippling equipment history and planning.

- Management Operating System (MOS) elements were either missing or inconsistently applied: in one process, 67% of MOS elements were not utilized.

- Operators and supervisors lacked visibility into daily production goals, OEE drivers, and root cause analysis. Variances were accepted rather than investigated.

POWERS identified more than $5 million in annualized improvement potential through throughput gains, reduced conversion costs, and improved reliability.

The Plan

POWERS installed a full Management Operating System across production and maintenance, embedding both tools and behaviors:

Frontline Leadership Tools

- Daily Weekly Operating Report (DWOR) for visibility of production vs. goals.

- Tiered Meeting Structure and Shift Huddles to cascade metrics and drive accountability.

- Daily Schedule Control and Short Interval Control (SIC) to keep teams focused on throughput.

- Gemba Walks, Leader Standard Work, and Effective Meeting Assessments to change supervisory time use.

- Skills Flex Matrix and structured operator training to rebuild capability and mitigate experience loss.

Maintenance MOS

- Full planning, scheduling, and kitting process.

- Accountability for contractors with defined scope, follow-up, and measurement.

- Root Cause Analysis and Sustainability Audits to ensure ongoing improvement.

Through leadership coaching and structured routines, POWERS shifted supervisors from firefighting to proactive problem-solving and engagement with their teams. Operators gained clarity on goals, metrics, and ownership of performance. Maintenance transformed from “winging it” to managing a disciplined backlog and improving reliability.

The Results

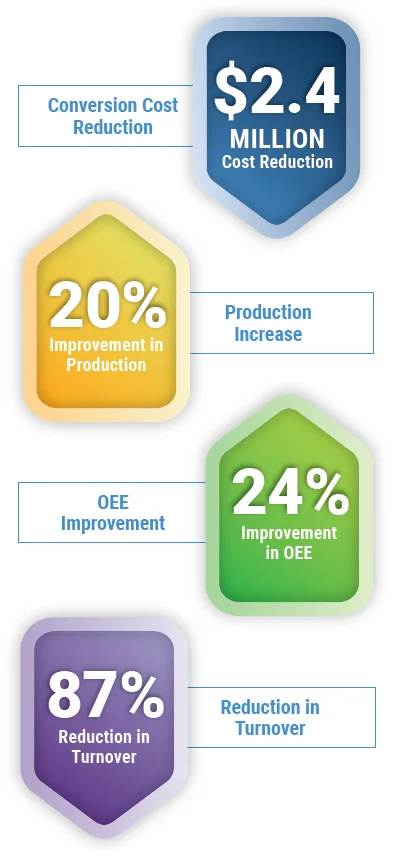

In just seven months, the facility achieved dramatic, measurable gains:

- Production: +19.8% vs. prior 7 months, +19.7% vs. prior year (805,148 MT).

- Conversion Costs: $2.36M reduction, equating to $8.63/MT improvement (25%).

- OEE: Jumped from 71% pre-project to 95%.

- Maintenance: Contractor accountability increased and as a result, costs reduced by $1.48 million annualized.

- Quality: Claims fell by $927,000 annualized; customer complaints dropped 68% vs. prior year.

- Safety: Recordables down 33%; Lost Workday Cases held flat.

- Workforce Stability: Median years of experience rose nearly 20%, reducing turnover from 54% to 7% in a 12-month period.

- Annualized Savings Impact: More than $5 million, with sustainability built in through a robust MOS and leadership coaching.

Conclusion

Through systems, leadership, and maintenance excellence, POWERS helped this global nutrition company recover from instability and build a sustainable, high-performance operation. The plant shifted from reactive firefighting to disciplined execution, capturing capacity that had been left on the table and reducing costs across the board.