Our client faced the cumulative effects of massive customer demand combined with the lingering impact of pandemic labor challenges and turned to our team to rapidly improve productivity.

Project Overview

Performance Results

Background

Our client is a large-scale poultry processor for one of the largest mass-market retailers in the world. Their recently completed, state-of-the-art facility was brought on line to serve the retailer’s commitment to providing only the highest quality products for its customers.

Despite its relatively short tenure in business, this facility has grown to be one of the region’s largest poultry producers and a welcome boon to the surrounding community.

Situation

This poultry processing powerhouse struggled with the combined challenges of being one of a few chicken processing plants in their region with the added chaos of being hard hit by the pandemic.

Though the top leadership had years of chicken processing experience, they had to draw on local talent unfamiliar with the challenges of running a chicken plant to run its day-to-day operation.

The young team assembled was brought on board during the pandemic and had grown accustomed to managing by survival, given their extreme resource challenges. It was time to teach the team how to manage.

Hitting planned case counts was the main objective of the management team. Yield and labor waste were not daily metrics they used to drive the business and, in some cases, had become so commonplace that management could not even see them.

In an extreme example, whole birds littered the floor around the Deli Line. Critical performance metrics, including yield data, were not incorporated and visible on the production floor.

Mass Retail Poultry Processor Racks Up Massive Productivity Gains With Over $6M in Savings and 6% Yield Increase With POWERS

Our client faced the cumulative effects of massive customer demand combined with the lingering impact of pandemic labor challenges and turned to our team to rapidly improve productivity.

Background

Our client is a large-scale poultry processor for one of the largest mass-market retailers in the world. Their recently completed, state-of-the-art facility was brought on line to serve the retailer’s commitment to providing only the highest quality products for its customers.

Despite its relatively short tenure in business, this facility has grown to be one of the region’s largest poultry producers and a welcome boon to the surrounding community.

Situation

This poultry processing powerhouse struggled with the combined challenges of being one of a few chicken processing plants in their region with the added chaos of being hard hit by the pandemic.

Though the top leadership had years of chicken processing experience, they had to draw on local talent unfamiliar with the challenges of running a chicken plant to run its day-to-day operation.

The young team assembled was brought on board during the pandemic and had grown accustomed to managing by survival, given their extreme resource challenges. It was time to teach the team how to manage.

Hitting planned case counts was the main objective of the management team. Yield and labor waste were not daily metrics they used to drive the business and, in some cases, had become so commonplace that management could not even see them.

In an extreme example, whole birds littered the floor around the Deli Line. Critical performance metrics, including yield data, were not incorporated and visible on the production floor.

Analysis

Because key metrics were not being looked at hourly or daily, results were monitored by the most uncomplicated metric to follow – cases produced. As a result, they did not understand the yield loss and labor inefficiencies in each area.

Due to the lack of KPI visibility, it was difficult to understand the performance issues and how to put corrective measures in place since days had passed from the occurrences. Senior leadership owned the problems instead of developing accountability with frontline leaders on the shop floor. As a result, critical issues remained unaddressed.

Leadership

Our LAB (Leadership Attitudes and Behaviors) assessment indicated that understanding the principles and practices required for high performance and acceptance of those responsibilities becomes marginal at the manager level and becomes unsatisfactory as you reach the frontline supervisors and team leads.

More so, the analysis uncovered that no one in the frontline supervisor or lead roles clearly understands these required skills and practices. Essentially the 2nd Processing Management Team was operating at one or two levels below where they should have been.

The company promoted frontline leaders into their current roles due to their past expertise in task execution. However, they have not been provided formal leadership training and coaching to make their transition into leading versus doing easy or successful.

In some instances, the company hired frontline leaders from outside the industry without clear direction or training on leading their teams. Lack of balanced performance objectives and coaching on achieving them created an environment of 'do whatever it takes to get cases out the door.

Management Operating System

The 2nd Processing Management Team confirmed that only 54% of the essential elements within an effective Management Operating System (MOS) were present within the company. Upon review, 63% of that 54% were not being utilized. Production areas were not responsible for reporting their performance to the upper levels.

No one was responsible for creating or assigning action items to address critical performance shortfalls. As a result, production suffered the same performance issues day after day. Frontline supervisors were not communicating with the operators to align their tasks, inform them of problems, and address quality issues until well after the fact.

There were no Visual Management tools in production areas to engage and inform the operators on essential metrics of quality, yield, and throughput performance on an hourly or daily basis. Unused real-time trimmer evaluations created a gap in communication with the trimmers on how they performed against established targets.

The only performance measure referenced throughout the plant was product case count. However, it was never reported or evaluated as a percentage of a goal but instead as yes or no. In the vacuum of an effective MOS, the 2nd Processing Management Team was left helpless to effect any change to the production situation, which further exacerbated a victim culture without performance measures.

Plan

We intended to increase throughput and yield recovery through capability run rates, line balancing, and shop floor KPI development. The POWERS team first implemented a robust Management Operating System designed to meet our client's performance goals on all production lines across all shifts.

We also focused on the 2nd Processing Area Manager's roles and responsibilities to drive the overall productivity goals and worked with the Plant Manager to develop the required management disciplines. Through leadership development, training, and coaching during execution, we taught them how to recognize variances in performance and root cause analysis generating actions to remove, resolve, or mitigate through permanent resolution.

In addition, we established short interval regimens with the frontline managers, supervisors, and team leads to engage with their line team members more proactively. This more robust team interaction drove departmental and overall plant success. In addition, it fostered greater variance recognition and more effective corrective actions to remove or minimize the issue until the team resolved it permanently.

Results

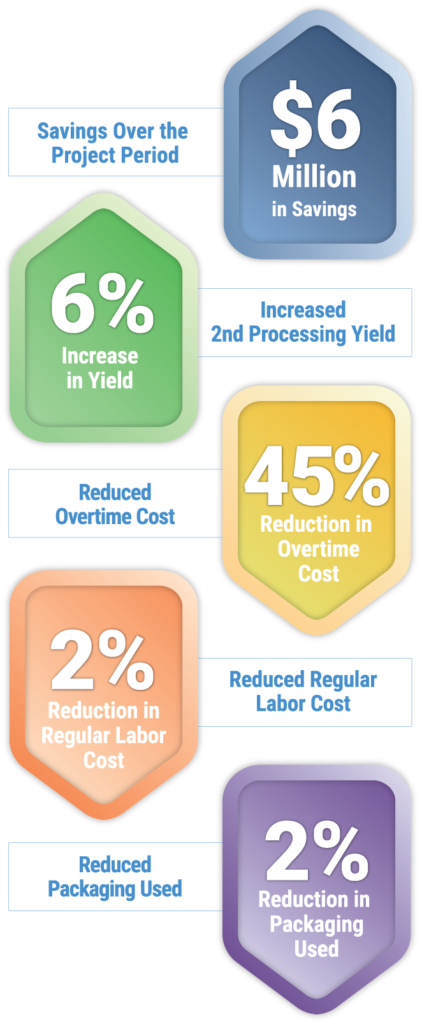

- $6M Savings Over the Project Period

- 6% Increase in 2nd Processing Yield

- 2% Reduction in Regular Labor Cost

- 45% Reduction in Overtime Cost

- 2% Reduction in Packaging Used

Additional Detail

Whole Bird Condemned Reduction

Whole bird condemned reduced by 48% (improving the daily yield) by fostering awareness of leak points on the line where whole birds were hitting the floor, improving the flow so as not to overload those areas.

Marinade Recovery Cumulative Savings

Marinade for the Deli WOG (Without Giblets) recuperation generated $450k in savings by installing drip pans that recycled the marinade, thus reducing the condemn.

We further mitigated marinade loss by improving end-of-production management so that operators were not dumping large volumes of marinade down the drain. We achieved this additional loss recovery by improving communication between the Marinade Room and Production Floor so that production tapered off to meet the remaining production demand versus overproducing.

Additional design changes to the Marinade Room allowed for the holdover of a small portion (500 gals) of the marinade as required.

Personnel Start Times

We adjusted personnel start times to better align with the timing of the product hitting the production floor, generating 50 hours per day of productive time.

Metal Detector Improvements

38% reduction in average condemned lbs. from the previous month through improved machine knowledge and setup. Additionally, our team developed Standard Operating Procedures (SOP) to aid in the training and management of product rejections to prevent false positives.

White Meat Yield Improvements Gained $415,340

In the highly automated system our client used, it was commonplace that constant changes were allowed during a production day with little to no understanding or data to determine if the changes actually improved performance.

Finally, manufacturing engineers were called in to recalibrate the White Meat breast filet harvester and locked down all system configuration settings once completed.

From that point onward, after instilling the root cause of variance discipline, the automated system performed exceptionally well with any further setting changes or adjustments predominately made through machine mechanical setup improvements.

Our team uncovered no company wide understanding of the White Meat grading standard. This dilemma caused miscommunication between line functions and departments. As a result, we retrained the existing grading standard and developed Visual Aids to ensure a shared understanding and language existed regarding downgrades.

White Meat trimmer assessments were developed, documented, and performed daily to ensure a clear understanding of quality downgrades, followed by accurate trim decisions to minimize the amount of meat removed to upgrade the product to Grade A or better.

We further improved White Meat yield with adjustments to the wing cutter setup, which reduced the cut depth and reduced the breast filet shoulder loss.

Dark Meat Yield Improvements Gained $1.6M

We found a critical function of the thigh harvester had been removed in previous years resulting in the inability to consistently harvest the thigh “oyster” from the back of the chicken.

As a result, 80% of the oysters were lost in production, an annual loss of $4M. We developed and executed an Action Plan to procure, reinstall, and maintain the Rotating Blade assemblies at the end of the project.

Wing Yield Improvements

Wing Yield improvements gained 1% through improved grader staffing and grading discipline. A grading SOP was developed and trained, which required hourly audits on the downgrade combos which could result in full regarding of the combo if a high percentage of audit volume were found to be grade A.

Wing tips were introduced into MSC. Previously these by-products were being sent to Offal to be sold at $0.14/lb. Approximately 10,000 pounds per day are now sent to MSC for processing at a 24% Yield at $0.68/lb.

Design Change

Design change was implemented to use thinner covers on the SaddlePack Line, and as a result of the 60% reduction in leaks, station manning was reduced from 2 to 3 employees to a maximum of 1.

Reallocation of Labor

Analysis of the Line Balancing in Deli resulting in reconfiguration of the "as-is" staffing.

Reallocation of labor of the 12 positions/day in the Bag Puller function yielding $463,680 annually in availability to reallocate resources without additional hiring.