Facing significant operational and cultural performance challenges, POWERS facilitates rapid and sustainable improvements.

Project Overview

Performance Results

Background

Our client is a private equity firm and their portfolio company is in the business of sourcing, processing, and marketing high-quality value-added food products from around the world to the foodservice and retail markets.

Their primary expertise is in coated products with world-class product development and processing capabilities to coat seafood and farm-fresh products utilizing the full spectrum of available coating formulas. From breadcrumbs and cracker meals to flours and batters, as well as flavor-infused glazes, they specialize in making products that taste great and are easy to prepare.

Situation

When we first engaged with our client, they faced significant operational and cultural performance challenges that prevented them from fulfilling customer orders and inhibited market share growth.

- Struggled to scale outmoded paradigms that had worked for years

- Faced a generational management transition, as retiring managers take their years of experience with them

- With numerous orders behind schedule

- manufacturing was choosing to operate sub-optimally, with minimal production runs

- Lost Time was nearly equal to production time

- No One Point Lessons (OPL) learned or even existed at the execution level

- The company operated on a “whatever it takes to get it out the door,” mentality

- A workplace culture of constant firefighting

Background

Our client-partner is in the business of sourcing, processing, and marketing high-quality value-added food products from around the world to the foodservice and retail markets. Their primary expertise is in coated products with world-class product development and processing capabilities to coat seafood and farm-fresh products utilizing the full spectrum of available coating formulas. From breadcrumbs and cracker meals to flours and batters, as well as flavor-infused glazes, they specialize in making products that taste great and are easy to prepare.

Situation

When we first engaged our client-partner, they faced significant operational and cultural performance challenges that prevented them from fulfilling customer orders and inhibited market share growth.

Our client-partner struggled to scale outmoded paradigms that had worked for years or things “they used to do.” They also faced a generational management transition, as managers who had been there for 20+ years were getting ready to retire and take their years of experience with them.

With numerous orders behind schedule and customers to please, manufacturing was choosing to operate sub-optimally, with minimal production runs to satisfy the most customers.

As a result, their Lost Time was nearly equal to production time, with no One Point Lessons (OPL) learned or even existing at the execution level. Instead, the company operated on a “whatever it takes to get it out the door,” mentality producing a workplace culture of constant firefighting.

Analysis

Our analysis revealed that our client-partner could not reliably plan or forecast resource requirements due to inaccuracies and a lack of trust in their new ERP system. Our observations on staffing levels and line balancing supported these findings.

They were operating without a schedule, utilizing “hotlists” that shifted constantly. In other words, the squeakiest wheel, whether sales or customer, was getting the grease. This failure in scheduling created a constant state of production firefighting with more frequent than optimal changeovers and additional production challenges.

Without a unified production schedule, they could not reconcile how they would distribute production resources to meet individual needs.

The lack of a production schedule also greatly hindered production floor control, as there was no line schedule from which the supervisor could assign operators. As a result, supervisors and production managers spent tremendous time determining what needed or could be worked on instead of proactively managing the effective execution of that work, producing a lack of visibility of the correct labor cost.

And finally, there were no operating reports to indicate line performance, resulting in little understanding of how well any individual production line was performing. This lack of reporting was compounded by a culture wherein past performance was never evaluated at the process or line level.

Solution

The POWERS team worked with production supervisors to construct line balance and SMED (Single Minute Exchange of Die) observations to ensure unique SKUs were set with reasonable expectations.

Working with the planning department, we developed a capacity model for the operation, enabling both short-term line scheduling and longer-term planning and forecasting the company’s resource needs.

Through on-the-floor frontline leadership support, we helped significantly improve short interval scheduling, follow-up, and barrier identification at the supervisory level. These improvements allowed frontline leadership to identify barriers better and to take actions to address any variance.

Working with the production team, we developed Lost Time capture to the root cause and implemented actions to improve output and more closely perform to their capacity.

With the help of IT, we implemented tablets for use on the floor and data migration to operating reports which illuminated production performance for management, identified production variances down to the sub-line level, and closed the feedback loop to scheduling.

Results

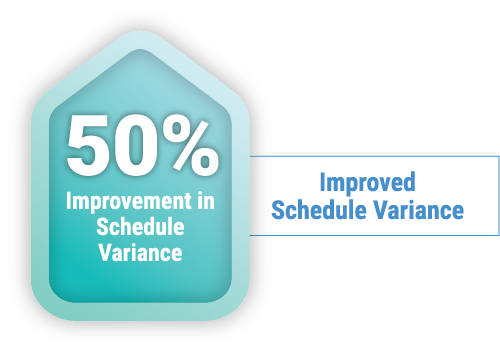

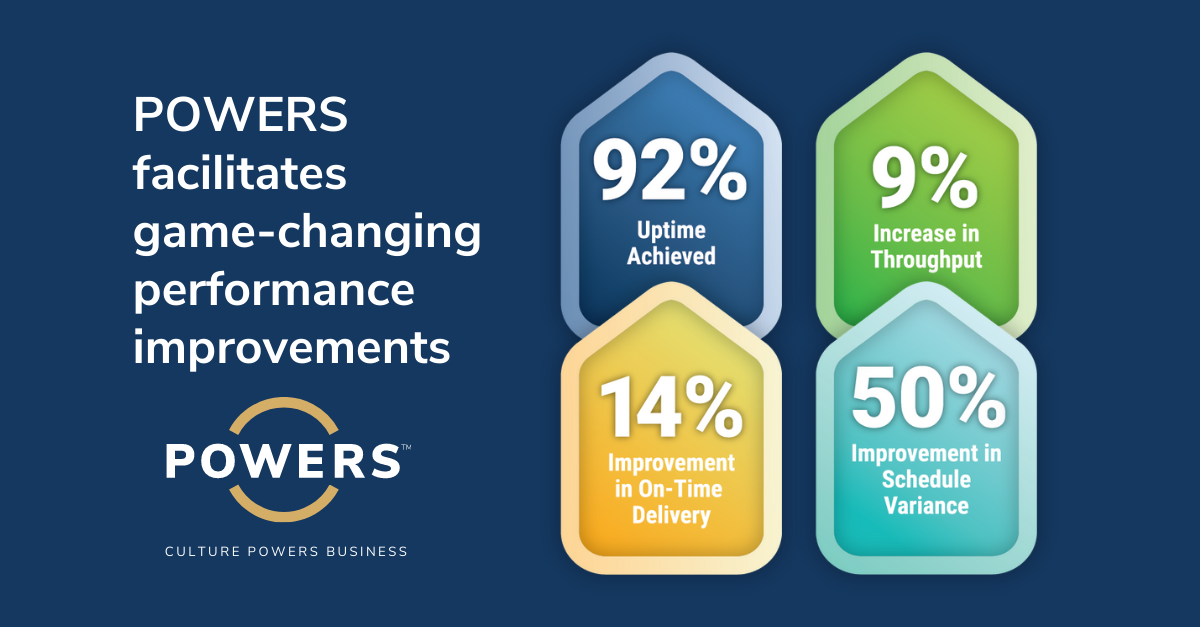

Time studies and feedback loops between production management and support areas led to a 50% increase in scheduling accuracy (reduction of variance in pounds scheduled to pounds produced).

Schedule execution and focus on Customer Due Dates have led to fewer expedites and an increase in on-time performance from 78% to 92%.

92% uptime was achieved by improving changeovers through SMED analysis, focusing on start-up, maintenance rebuilds of problem equipment, and lost time RCCA (Root Cause and Corrective Action).

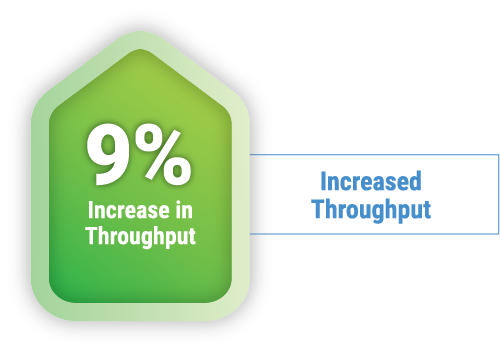

With a clearer picture of the schedule, more organized staffing, and employee buy-in, production saw a 9% increase in daily pounds produced.

The improved communication feedback loops and work execution we facilitated have led to priority focus instead of a broad view where everything was priority one.