Project Overview

About the Manufacturer

This partner is a vertically integrated contract manufacturer specializing in shelf-stable, ready-to-drink beverages. Their capabilities span product development, processing, packaging, and supply-chain coordination, providing brand owners with a streamlined path from concept to scaled production. With flexible packaging options and a strong focus on quality and consistency, they support reliable execution as demand grows.

The Challenge

A repeat manufacturing client launched a new product line and quickly began experiencing quality and damage issues as demand scaled faster than their supporting processes. Product was moving from raw materials through a co-packing operation and into customer distribution centers, but quality failures were occurring at multiple points across the flow.

Performance Results

Read the Full Case Study Here

Leadership needed a clear, end-to-end view of the process, immediate containment of losses, and a scalable system that would hold as volumes increased.

POWERS was engaged to diagnose the breakdowns, stabilize execution, and establish a repeatable operating standard across internal teams and external partners.

What We Found

Through a full process walkthrough and data review, our team identified more than 100 discrete issues contributing to product damage and quality escapes. Key breakdowns included:

- Inadequate quality checks on the production line

- No formal inbound inspection process from the co-packer

- No outbound load inspection prior to shipment

- Insufficient cardboard strength and packaging design

- Poor load patterns and inconsistent use of dunnage

- Limited feedback loops between the manufacturer, co-packer, and customer

These gaps created high failure rates, rework, and damaged product arriving at customer distribution centers.

What We Did

The POWERS team applied a focused 14-week DMAIC engagement to stabilize the system and build long-term capability.

Process Control & Inspection

- Defined and implemented 16 critical inspection points across the end-to-end process

- Developed standard operating procedures and trained teams at each control point

- Built structured inbound and outbound auditing processes to prevent defects from moving downstream

Packaging & Load Optimization

- Partnered with packaging engineers to redesign cardboard packaging, reinforcing the product base and reducing movement during transit

- Established standardized load patterns and trained forklift operators to ensure consistency

- Reduced load shifting and damage during transportation

Supplier & Partner Alignment

- Facilitated working sessions with the co-packer and customer to surface pain points and align expectations

- Implemented structured feedback loops to drive accountability and continuous improvement

Quality System Reinforcement

- Mapped the full process flow and embedded the inspection points into a reinforced quality management system

- Developed a documented “gold standard” defining the minimum operational and quality requirements all future co-packers must meet to do business with the client

The Results

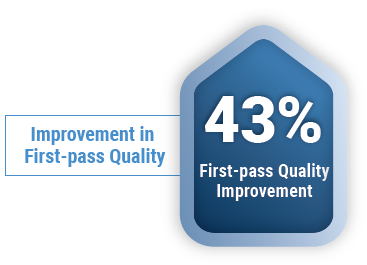

- Outbound loads passing first-pass quality improved from 49% to a sustained 70% average within four weeks

- Represented a 43% improvement in first-pass quality

- Significant reduction in damaged goods reaching customer distribution centers

- A scalable quality system capable of supporting continued volume growth

The DMAIC Methodology in Practice

DMAIC provides a structured, data-driven approach for improving existing processes that are underperforming or failing to meet customer expectations. POWERS uses DMAIC as a practical execution framework, not a theoretical exercise.

Define

Clarify the problem, scope the process, align on customer requirements, and establish measurable improvement goals.

Measure

Establish baseline performance using reliable data and identify the metrics that matter most to the operation.

Analyze

Identify and verify root causes using structured problem-solving tools to ensure effort is focused on the true drivers of failure.

Improve

Design and implement targeted solutions that directly address verified root causes. Pilot where necessary, then standardize.

Control

Put systems in place to sustain gains through clear standards, audits, and accountability mechanisms that prevent regression.

Why This Matters

Rapid growth exposes weak processes. Without clear controls, quality systems, and partner alignment, scale amplifies losses instead of results.

This engagement helped the client stabilize execution, protect customer relationships, and build a foundation capable of supporting future growth without repeating the same failures.