Project Overview

Background

A large, multi-site food and ingredients manufacturer operating a complex processing facility was experiencing rising operating costs, inconsistent execution across shifts, and uneven compliance to its Structured Management System (SMS). While many of the right tools and processes existed on paper, they were not being consistently used to guide daily decisions or leadership behaviors.

As a result, leaders were spending a disproportionate amount of time reacting to issues rather than preventing them, and frontline teams lacked clarity on priorities, performance expectations, and what constituted a successful day.

POWERS engaged to help stabilize execution, reinforce leadership discipline, and translate SMS principles into daily behaviors that drive measurable and sustainable results.

Objective and Scope

The engagement was designed to improve operational performance by aligning leadership behaviors, operating rhythms, and frontline execution to a structured management system that could be consistently applied across all shifts.

Specific objectives included:

- Increasing throughput and equipment reliability

- Reducing yield losses and operating cost variability

- Aligning staffing levels to actual workload demands

- Clarifying and reinforcing KPI ownership at every level

- Building leadership capability to recognize performance variance and act decisively

Rather than focusing solely on technical fixes, the POWERS team emphasized leadership execution, standard work, and the routines required to sustain performance over time.

Performance Results

Read the Full Case Study Here

Approach

From the outset, the POWERS team worked side-by-side with plant leadership, supervisors, and frontline teams to observe real work, understand current behaviors, and identify where execution was breaking down.

The approach centered on making the existing management system operational, not theoretical.

Key focus areas included:

- Leadership Role Clarity and Standard Work

Our team facilitated role and responsibility alignment workshops, translating expectations into clear, observable standard work for leaders at every level. This ensured supervisors, superintendents, and managers understood how they were expected to spend their time and what “good” looked like in daily execution. - Short-Interval Control and Daily Management Routines

The POWERS team installed and coached daily schedule control and short-interval control routines, reinforcing consistent cadence, escalation, and accountability. Leaders were coached in real time on how to recognize variance, ask better questions, and drive corrective actions on the shop floor. - Variance Recognition and Root Cause Discipline

Our team trained leaders to move beyond symptom chasing and apply practical root cause analysis tied directly to standards. Corrective actions were expected to remove barriers permanently, not temporarily mask issues. - Frontline Engagement and Team Ownership

Through observed shop floor interactions, coaching, and feedback, the team helped leaders shift toward more consistent, servant-leader behaviors. This improved communication, strengthened trust, and increased frontline ownership of performance. - Maintenance and Contractor Cost Control

The POWERS team worked closely with maintenance and operations leaders to improve execution of an existing maintenance management playbook, strengthen contractor oversight, and elevate technical capability within the workforce.

Early identification and execution of quick wins helped build confidence, while improved data discipline and visual management tools allowed teams to clearly understand performance expectations and identify additional opportunities.

Engagement Overview

- Duration: 36 weeks

- Team: Up to seven POWERS consultants embedded on site

- Scope: Operations, Maintenance, and Quality

- Focus: Sustainable execution, leadership capability, and SMS compliance

Throughout the engagement, the combined POWERS and plant leadership team focused on building internal capability. A sustainability and audit process was designed and implemented to ensure leaders could continue measuring compliance and performance long after the engagement concluded.

Results

The results significantly exceeded expectations, both financially and operationally.

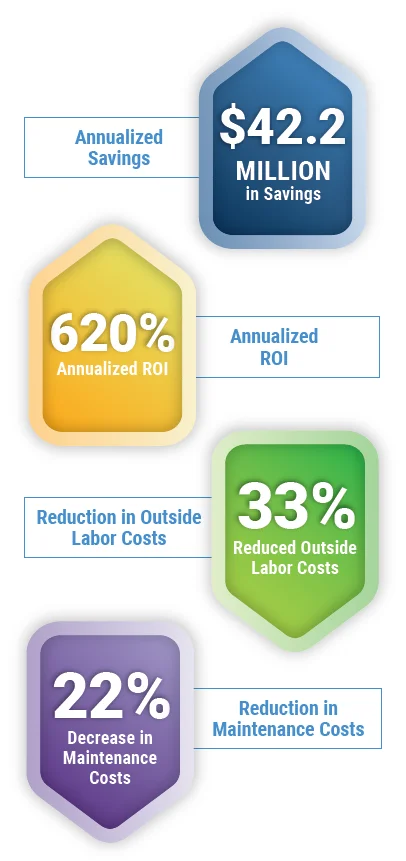

Financial Impact

- Planned annualized savings: $6.8M

- Actual annualized savings: $42.2M

- 620% annualized ROI

Operational Cost Improvements

- Outside labor costs reduced 33.5% against a 15% target

- Outside repair and maintenance costs reduced 22.7% against a 12% target

- Savings achieved without reducing work volume or compromising quality

Leadership and Execution Improvements

- Clear alignment of roles, responsibilities, and decision rights

- Standard work established and sustained across leadership levels

- Consistent use of daily management and short-interval control routines

- Improved quality of shop floor engagement and feedback

- Effective implementation and reinforcement of maintenance management practices

- Stronger root cause analysis discipline with corrective actions tied to permanent solutions

As leadership behaviors became more consistent, the operation moved from reactive firefighting to predictable execution. This stability allowed leaders to spend more time improving the system rather than recovering it.

Takeaway

This engagement demonstrates that meaningful performance improvement does not come from introducing more tools, but from how leaders use the tools they already have.

By working alongside the plant team to operationalize the management system, reinforce leadership discipline, and embed structured routines into daily execution, the facility achieved outsized financial returns and built internal capability to sustain performance improvements well beyond the engagement.