Project Overview

Background

A large pork processing operation in the Midwest was facing performance issues across the board. The facility, which included both slaughter operations and downstream packaged goods production, was struggling to meet sales commitments while also dealing with yield losses, workforce challenges, and coordination breakdowns.

The company, with more than $1 billion in annual revenue, had significant room for improvement but no clear path to close the gap. Sales orders were often misaligned with what the plant could produce. Yield losses on high-value primal cuts were driving up cost per pound. And a transient, hard-to-retain workforce made it difficult to maintain steady output on the floor.

They brought in POWERS to build better systems, align production with demand, and develop frontline capability. In just 40 weeks, the engagement delivered more than $10.8 million in annualized savings through a combination of operational, supervisory, and strategic improvements.

Performance Results

Read the Full Case Study Here

What Was Going Wrong

- Sales vs. Production Misalignment: The plant often struggled to produce what had already been sold. This led to missed orders, empty trucks, demurrage fees, and canceled loads.

- Overproduction and Discounting: At the same time, overproduction of the wrong items created excess inventory that had to be sold off at reduced prices, cutting into margins.

- High Yield Losses: Giveaway on valuable cuts added up fast, eroding profit on every pound sold.

- Workforce Instability: Constant turnover meant teams were always short-handed, especially in the most skilled roles. And when new hires did come in, they took too long to get fully productive.

- Reactive Maintenance: Equipment reliability was an issue, and much of the maintenance work was unplanned, resulting in excessive overtime and frequent interruptions to production.

What the Company Needed

- A way to tightly align production schedules with confirmed sales orders

- Better yield performance, especially on high-margin cuts

- A faster ramp-up process to get new employees functional quickly

- More day-to-day visibility and responsiveness on the shop floor

- Stronger connection between executive priorities and frontline execution

- A structured approach to planning and executing maintenance

What POWERS Did

POWERS deployed an integrated strategy to address both operational gaps and leadership execution. This wasn’t a one-size-fits-all solutionit was a hands-on, data-driven effort grounded in daily plant realities.

We focused on performance habits, supervisor development, and practical systems that empowered each level of the organization to execute more effectively.

Key components included:

- Daily Schedule Control & Yield Visibility

We introduced short-interval follow-up systems that helped production teams monitor throughput, yield, and staffing in real time. Visual metrics boards made performance easy to track at a glance, keeping everyone focused on shift priorities. - Supervisor Coaching & Support

Frontline leaders were coached on how to manage people and performance more effectively. This included real-time coaching on problem-solving, reinforcing key behaviors, and holding teams accountable for daily results. - Shift-Based Yield Tracking

Yield was no longer just a number reviewed at the end of the day or week. Reports were broken down by shift and available in real time so that small losses could be corrected before they turned into big ones. - Maintenance Operating System

Maintenance was shifted from reactive to more planned and controlled. Scheduling protocols, daily priority checks, and coordination with production teams helped improve uptime and reduce costly after-hours work. - S&OP: Frontline™ Planning Process

We established a structured method for connecting the sales forecast and production capacity. This helped prevent overproduction, reduced excess inventory, and allowed for more consistent order fulfillment.

The Results

By the end of the 40-week engagement, the company had improved across every targeted areaand locked in sustainable savings that would continue to grow.

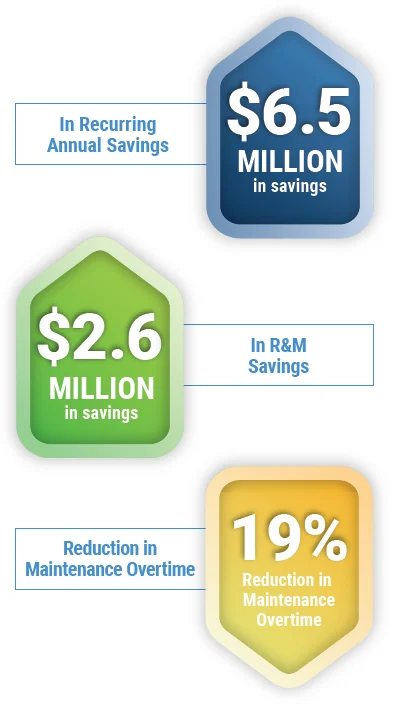

- $6.5 million in yield recovery, thanks to tighter controls and behavior-based improvements on the cut floor

- $2.6 million in R&M savings, through more efficient use of maintenance labor and improved equipment reliability

- 19% reduction in maintenance overtime, saving another $800,000 annually

- Shortened ramp-up time for new hires, improving workforce effectiveness and reducing strain on experienced employees

- Better order fill rates, fewer last-minute cancellations, and improved shipping logistics

- Increased trust between production, sales, and planningbuilt on a shared system and shared data

POWERS works directly with manufacturers to identify gaps, develop people, and build processes that perform. If you’re facing yield loss, staffing instability, or poor coordination between sales and operations, our team can help. We don’t just analyzewe get on the floor and build systems that last.

Let’s talk about what’s holding your performance backand how to move forward.