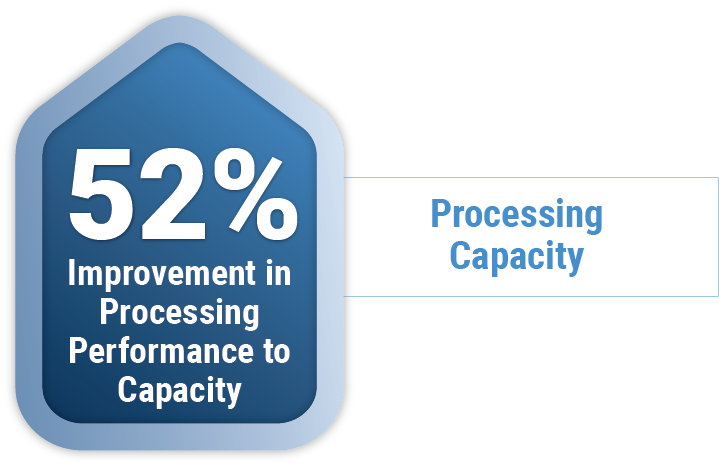

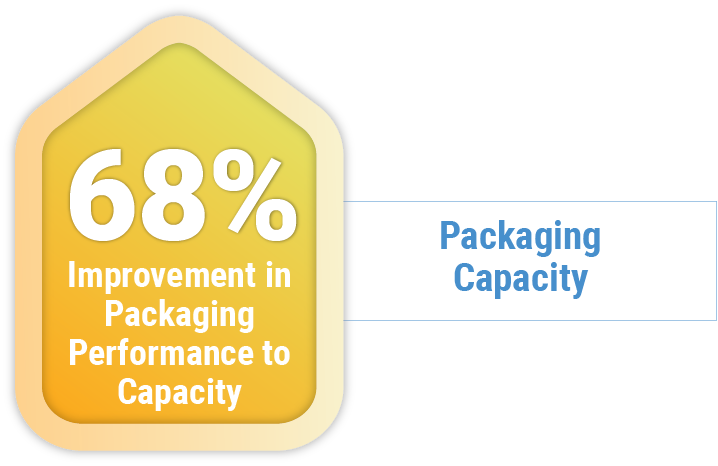

POWERS Improves Processing Capacity, Final-Pass Quality, Packaging Capacity, and Reduces Packaging Waste for Pet Food Industry Leader

Project Overview

Performance Results

POWERS partnered with a key pet treats manufacturer facing first-pass quality and overall capacity performance issues in their manufacturing process. The client’s products are in high demand, and due to poor first-pass quality, the business was building a backlog of orders. The resulting first-pass quality issues resulted in raw yield loss, poor line utilization, and poor labor utilization.

Additionally, like many industries across the country, employee turnover was high, and the ability to pull from the current labor market has proven difficult.

During our discovery process, we identified that the operational culture was not aligned with the overall goals and company culture that our client wanted to reflect. The front-line leadership team did not receive the training or possess the skills to make performance-based business decisions aligned to company goals. High waste and poor performance were the results of the inherited company culture.

Historically our client, under prior ownership, applied a “top-down” leadership and communication approach. Managers and supervisors would do as directed and would not step out of those boundaries. Our client desired a culture organized around the optimal systems and processes that fostered ownership and accountability. They needed assistance in the training and development of their leaders’ skills and behaviors necessary to transform into a goal-oriented organization from the floor up.

We worked side-by-side with our client to create a sustainable Management Operating System in the Manufacturing, Packaging, Scheduling, and Maintenance departments.

Contact POWERS to learn more about the results of our partnership with this leader in the Pet Food Industry and how to put us to work improving your operational culture and performance.