Introduction: The Widening Chasm at the Heart of U.S. Manufacturing’s Digital Transformation

Imagine a bustling assembly line in a mid-west-based automotive aftermarket parts plant on a crisp Fall morning. Robots hum alongside workers, feeding data into connected machines that promise to streamline production and cut waste. However, the line grinds to a halt, not due to a mechanical failure, but because the frontline supervisor, overwhelmed by unfamiliar AI-driven analytics dashboards, hesitates to make a critical adjustment. This scenario isn’t fiction; it’s the stark reality for many U.S. manufacturers navigating the uneven terrain of digital transformation. As factories push toward smart operations, the human element often becomes the unintended roadblock, turning cutting-edge tools into sources of frustration rather than efficiency.

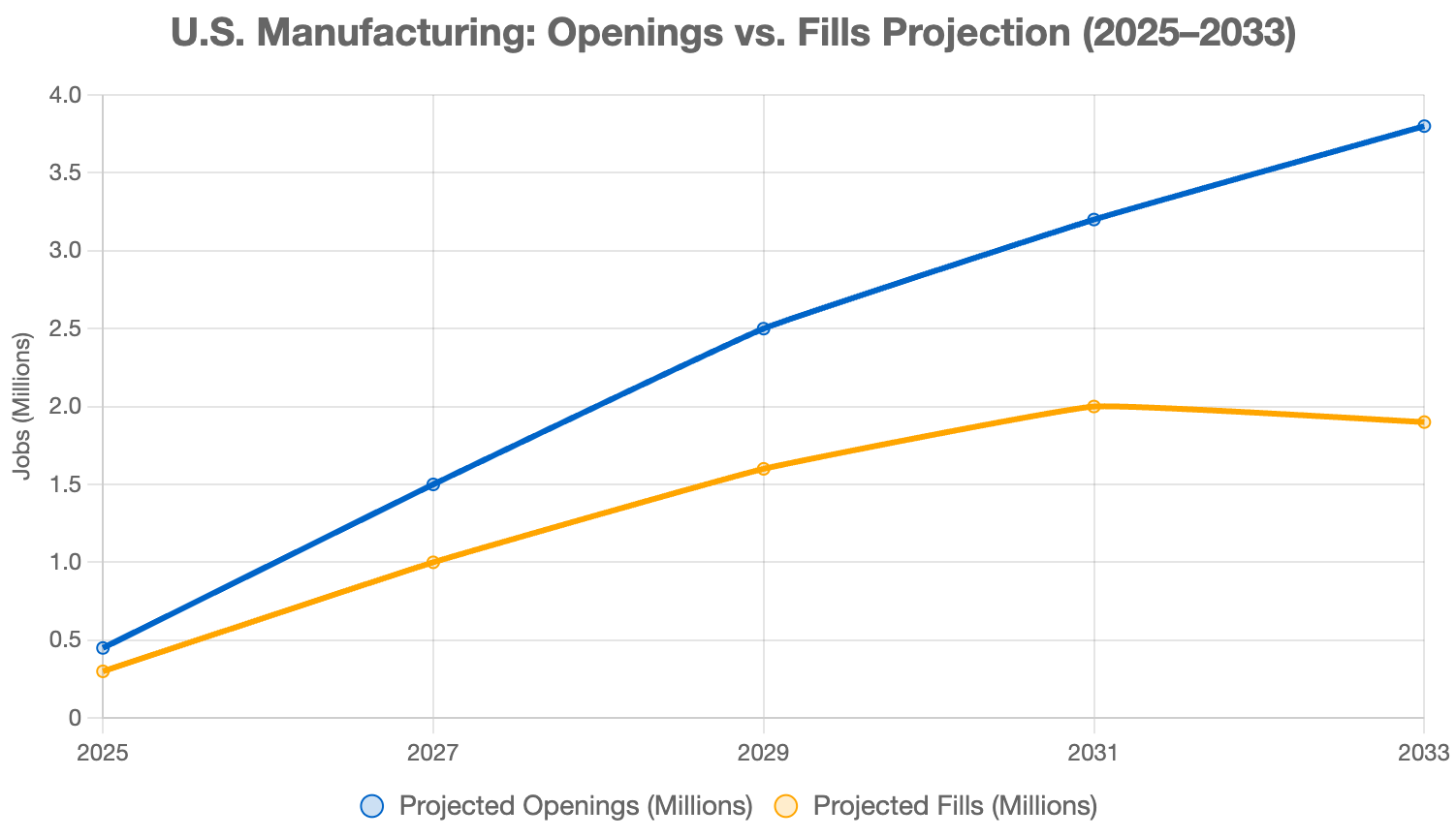

At the core of this tension lies the U.S. manufacturing skills and behaviors gap, a widening chasm between the competencies required for modern production and the workforce equipped to deliver them. In 2025, this gap manifests as delays in adopting automation, higher turnover among hourly workers, and stalled pilots for connected systems, resulting in billions of dollars in lost productivity for the sector. Projections paint a sobering picture:

By 2033, the industry could face 3.8 million job openings, yet up to 1.9 million of those positions might go unfilled due to talent shortages.

Nearly 60% of manufacturers already rank attracting and retaining employees as their top challenge, with quits rates hovering at 1.6% and replacement costs for skilled frontline workers ranging from $10,000 to $40,000 per hire. These aren’t abstract numbers; they represent real friction and bottlenecks in the daily grind of American factory production, from Midwest fabricators wrestling with legacy equipment to West Coast electronics firms eyeing reshoring opportunities.

This skills shortage isn’t isolated—it’s deeply intertwined with the dual waves of Industry 4.0 and the budding Industry 5.0. Industry 4.0, with its emphasis on IoT, AI analytics, and interconnected machines, is expected to see U.S. adoption reach about 50% for core technologies like IoT this year, fueled by a $21.4 billion market. Yet, for many small and medium-sized enterprises (SMEs), foundational hurdles persist: high capital costs, legacy system integration snags, and cybersecurity fears that escalate with every new connection. Enter Industry 5.0, still in its infancy but gaining momentum among larger players through human-centric pillars like resilience, sustainability, and collaborative robotics (cobots). North America leads globally, capturing the highest revenue share in 2024, with the market valued at $82.57 billion in 2025 and projected to surge to $2.15 trillion by 2037.

Federal initiatives, like the CHIPS and Science Act, are accelerating this shift by incentivizing domestic investments in AI-powered tools and edge computing that blend human ingenuity with machine precision.

But here’s the pivot: Technology alone won’t close the gap. Frontline leadership—those supervisors and team leads overseeing 80% of shop-floor operations—holds the key. Underinvested, they become friction points, amplifying resistance to new tools and exacerbating turnover. Empowered through targeted training, development, and accessible digital aids, they transform into accelerators, guiding teams from wary skeptics to confident collaborators. This guide explores that dynamic, offering a practical 5-step framework to equip frontline leaders for the U.S. manufacturing skills and behaviors gap, the demands of frontline leadership in 2025, and the execution ahead in 2026. Drawing on insights from the National Association of Manufacturers (NAM), Harvard Business Review, and recent industry outlooks, we’ll unpack the challenges, map actionable strategies, and spotlight real-world wins. In a year where manufacturing jobs have stabilized near 13 million and productivity hits all-time highs, bridging this gap isn’t just smart—it’s essential for survival in an era of simultaneous progression of Industry 4.0 and 5.0.

Mapping the U.S. Skills Gap: Frontline Leadership as Friction Point or Accelerator in Industry 4.0 and 5.0

The U.S. manufacturing landscape in 2025 is a tale of two revolutions: the entrenched struggles of Industry 4.0 adoption and the tentative optimism of Industry 5.0’s human-tech harmony. While larger corporations experiment with cobots and predictive maintenance, SMEs—comprising 98% of the sector—struggle with basic tasks such as integrating decades-old equipment with modern sensors. This uneven evolution spotlights the workforce skills gap as a frontline crisis, where leaders either perpetuate delays or propel integration.

Consider Industry 4.0’s foundational challenges. Despite a robust market, adoption lags due to significant financial barriers. Legacy systems, comprising over 70% of North American equipment older than 20 years, create interoperability nightmares, while cybersecurity risks deter connectivity expansions. The result? 70% of Industry 4.0 pilots fail, often not due to technical glitches but rather human factors such as inadequate training. Frontline leaders, tasked with daily oversight, bear the brunt: Untrained in AI analytics or robot maintenance, they contribute to 25% of integration downtime, turning promising tools into workflow bottlenecks. Industry analyses indicate that data quality and validation obstacles plague 70% of AI efforts, yet only 51.6% of firms have a coherent corporate strategy—leaving supervisors to improvise amid fragmented systems.

Layer on the emerging demands of Industry 5.0, and the gap sharpens. This evolution—projected to grow from $66.9 billion in 2024 to $312 billion by 2030 at a 19.54% CAGR—redefines manufacturing not as tech-dominant but human-amplified, emphasizing customization, sustainability, and resilience. U.S. momentum is evident in reshoring trends, where firms leverage CHIPS Act funds for AI-driven robotics and digital twins, extending beyond factories to logistics and healthcare.

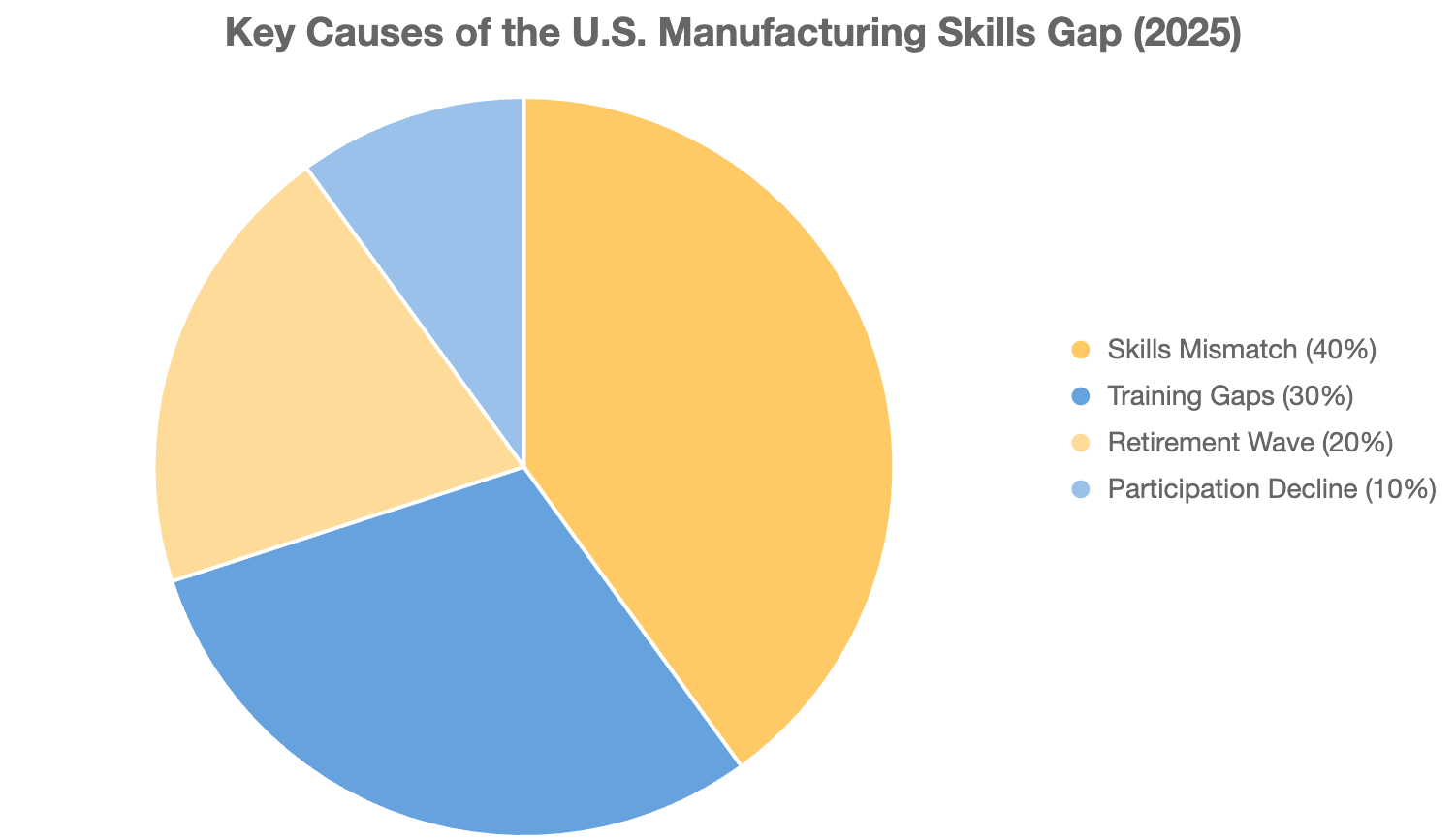

Yet, with 54% of workers needing upskilling by 2030, the transition exposes raw vulnerabilities. Over 450,000 manufacturing jobs stood unfilled in early 2025, fueling a $1 trillion labor crisis as retirees outpace entrants.

Frontline leaders managing hourly teams amplify this: poorly equipped, they foster resistance, which spikes turnover by 18% and delays rollouts by up to 30%. HBR research highlights how new leaders often feel isolated without clear norms, which can exacerbate loneliness and disengagement in high-stakes environments.

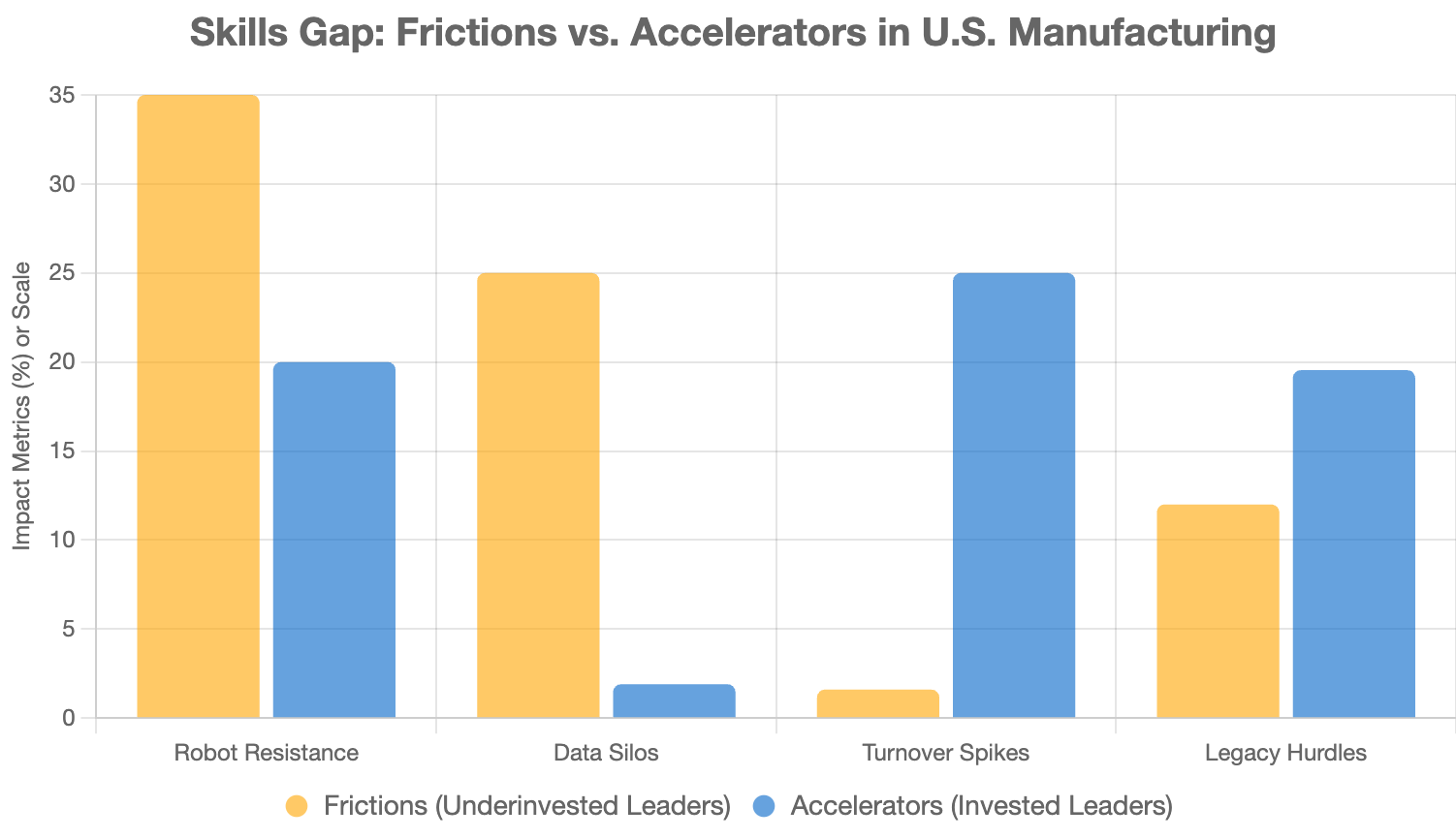

Skills Gap Frictions (Underinvested Leaders)

- Robot resistance leading to 35% delays

- Data silos causing 25% downtime

- Turnover spikes

- Legacy integration hurdles

Adoption Accelerators (Invested Leaders)

- Training yielding 20% efficiency gains

- Upskilling addressing 1.9M shortfall by 2033

- Engagement boosts via human-centric tools

- Cobot collaboration prepping for 5.0 resilience

Visualizing the Trade-Off: Frictions vs. Accelerators in the Skills Gap

The bar chart below contrasts the costly frictions from underinvested frontline leaders (orange bars: e.g., high delays or churn risks) with the gains from targeted investment (blue bars: e.g., efficiency boosts or growth potential). Note the mixed scale, frictions highlight pain points, while accelerators show upside ROI—to underscore how equipping leaders flips hurdles into opportunities.

This table, adapted from 2025 benchmarks, illustrates the duality. In SMEs still mastering Industry 4.0 connectivity, underinvestment manifests as reactive fixes and mistrust of AI tools. Forbes highlights how jobs linger vacant not from lack of applicants, but mismatched skills in industrial tech. Conversely, empowered leaders, through programs blending technical and soft skills, drive rapid uptake. IndustryWeek reports that digital tools, when paired with leadership development, re-energize workforces by clarifying roles in connected factories. As 3.8 million openings loom by 2033, with technical roles growing fastest, frontline investment isn’t optional; it’s the bridge from 4.0’s efficiency grind to 5.0’s collaborative promise. In reshoring hotspots like the Southeast, where supply volatility meets tariff pressures, leaders who foster trust in edge computing and cobots can slash misalignments, turning potential $1 trillion drags into productivity surges.

With employment stabilizing at 13 million yet participation declining for two decades, the path forward demands a people-first lens amid tech’s relentless march.

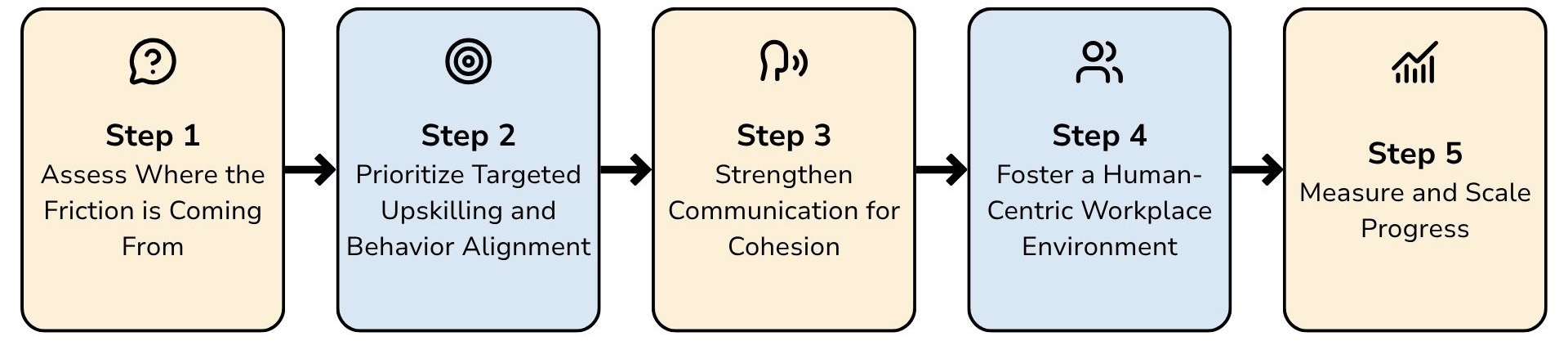

A Framework for Action: 5 Steps to Equip Frontline Leaders and Bridge the Gap

Closing the U.S. manufacturing skills and behaviors gap requires more than proclamations— it demands a structured approach that positions frontline leadership at the center. This 5-step framework, informed by our first-hand experiences, recent 2025 industry outlooks, and HBR’s reskilling imperatives, is designed for U.S. firms at any maturity: from SMEs bolting IoT onto legacy lines to larger players piloting Industry 5.0 cobots. Each step emphasizes investments in training, development, and tools, transforming leaders from friction amplifiers to integration catalysts. Expect measurable outcomes, like 15% efficiency gains in 90 days, as seen in NAM-backed transformations.

Step 1Assess Where the Friction is Coming From

Start with a thorough audit to identify where skills shortages and misaligned behaviors disrupt operations. Use anonymous surveys on tech confidence, behavioral observations (such as resistance to change or siloed decision-making), and workflow analytics from tools like DPS for tracking mission-critical KPIs. This reveals up to 80% of misalignments. For instance, it uncovers AI dashboard blind spots in legacy setups or leaders relying on top-down directives that limit collaboration. In sectors like semiconductors, where a 39% technician shortage persists, prioritize automation oversight and flag behaviors like risk aversion that block cobot adoption. U.S.-tailored diagnostics, informed by CHIPS Act data, expose not only technical voids but also behavioral gaps, such as poor change communication or low adaptability.

For example, an Ohio metal stamper in early 2025 applied this step to map 25% delays from unintegrated sensors. They prioritized robot handoffs while identifying habitual micromanagement as a key friction driver. Outcome: A baseline friction index to guide spending amid $12 million upgrade realities.

Step 2Prioritize Targeted Upskilling and Behavior Alignment

Using your diagnostics, launch modular training that builds both skills and adaptive behaviors. Focus on Industry 4.0 essentials, like IoT interoperability and basic AI analytics, and Industry 5.0 priorities, such as cobot safety protocols. Pair this with coaching for mindsets like embracing experimentation over perfectionism. Aim for 40% reductions in barriers through community college partnerships, as Indiana’s programs show in closing pipelines for 3.8 million future roles. Integrate soft skills too. HBR emphasizes mentoring to reduce frontline loneliness, which boosts retention and reinforces proactive behaviors like problem-solving.

A Midwest fabricator in Q2 2025 upskilled 50 supervisors on edge computing through virtual labs. They added role-playing to shift from reactive to collaborative habits. Result: 30% faster tool adoption, addressing the 54% retraining need without $10,000-per-hire churn.

Step 3Strengthen Communication for Cohesion

Break down silos with rituals like daily huddles tied to real-time data from connected machines. At the same time, promote transparent, inclusive behaviors that invite input from every level. Provide leaders with mobile apps for action logging to cut misalignments by 20%. This is vital for tariff-impacted supply chains. Reward open dialogue to build trust in Industry 5.0’s collaborative core. IndustryWeek notes that blending IT, OT, and ET systems clarifies roles, enhances cybersecurity trust, and amplifies behaviors like active listening.

In a Texas electronics plant with 18% turnover, leaders rolled out AI-augmented briefings for sustainability alignment. They also recognized team members who championed shared ownership. Gains: Smoother 4.0-to-5.0 transitions, with engagement up 15%.

Step 4Foster a Human-Centric Workplace Environment

Make leadership development ongoing by linking company values to tech ethics, such as ethical AI in Industry 5.0. Assess, train, recognize, and reward behaviors that emphasize accountability, innovation, and resilience over rigid hierarchies. Use performance metrics to celebrate collaborative successes, raising engagement by 25% and curbing 8% turnover spikes by highlighting adaptable leaders. Forbes promotes “capital T” talent. This means holistic growth in technical and interpersonal areas to counter retiring expertise and instill 5.0 habits like cross-functional teamwork.

A 2025 California reshoring effort integrated this via quarterly workshops, aligning 200 frontline staff on resilience while rewarding shifts to inclusive decision-making. Impact: 22% productivity increase, preparing for human-robot partnerships amid $1 trillion crisis warnings.

Step 5Measure and Scale Progress

Track progress with KPIs like overall equipment effectiveness (OEE) and indexes for both skills and behaviors, reviewing quarterly. AI-based tools for deployment tracking, expected to be standard by 2030, help scale from 4.0 pilots to 5.0 resilience by spotting and promoting high-impact behaviors. Surveys show 55% gen AI adoption, but true ROI depends on these feedback loops.

A Florida supplier achieved 15% throughput gains in 90 days, scaling cobot integrations while honoring behavioral leaders who accelerated team buy-in by 20%.

This framework isn’t theoretical; it’s battle-tested for the U.S. manufacturing skills gap frontline leadership 2025 reality, where 70% of digital efforts falter on humans. By investing ~30% of budgets in tech-human synergies, firms unlock the 19.54% CAGR of Industry 5.0, preparing resilient ops for 2026’s anticipated challenges like supply volatility.

Real-World U.S. Insights: Frontline Leadership Closing the Skills Gap in Action

The proof of any framework lies in application, and U.S. manufacturers are delivering compelling cases of frontline-led triumphs amid 2025’s skills turbulence. These stories, drawn from industry collaborations and IndustryWeek spotlights, show how targeted investments turn potential pitfalls into progress.

Take a classic Midwest fabricator, entrenched in partial Industry 4.0 with aging presses and sporadic IoT trials. Facing 25% line delays from data silos, leadership audited frictions per Step 1, revealing supervisor gaps in analytics interpretation. A six-month upskilling push (Step 2) via partnered bootcamps equipped 40 leads with cobot basics, while huddle protocols (Step 3) bridged team divides. Culture rituals, like “tech share” sessions (Step 4), embedded 5.0 sustainability, and OEE tracking (Step 5) confirmed 22% productivity lifts—slashing unfilled roles from 15% to under 5%. As NAM data underscores, such moves directly counter the 1.9 million shortfall projection.

Zoom to a Southeast automotive supplier leveraging reshoring winds.

Zoom to a Southeast automotive supplier leveraging reshoring winds. With CHIPS funds fueling robot influxes, early 2025 pilots stalled at 30% adoption due to resistance, echoing the 70% pilot failure rate.

Frontline coaches, developed through HBR-inspired mentoring (Step 4), reframed tools as enhancers, not replacers, cutting turnover via clear norms. Simulations for AI oversight (Step 2) accelerated fluency, yielding 20% faster integrations and positioning the firm for Industry 5.0’s human-AI ethics. Broader ripple: A 18% engagement surge, aligning with Forbes’ call to rethink blueprints beyond coding camps.

These aren’t outliers. In healthcare-adjacent manufacturing, like a Pennsylvania device maker, leadership investments mitigated the $1 trillion crisis by blending 4.0 connectivity with 5.0 customization—retraining 60% of staff for digital twins, per recent 55% gen AI benchmarks. The result? Resilient ops amid 450,000 vacancies, proving that equipping the frontline to win every shift scales from SMEs to giants. As 3.8 million openings beckon, these insights affirm: Invest in leaders, and the skills gap becomes a launchpad.

Conclusion: Empowering Frontline Leaders to Conquer the Skills & Behaviors Gap and Shape U.S. Manufacturing’s Future

In 2025’s hybrid horizon—and the 2026 pathways it unlocks—where Industry 4.0’s $21.4 billion tech foundations underpin Industry 5.0’s $82.57 billion human-centric surge—the U.S. manufacturing frontline leadership skills and behaviors gap challenge boils down to one truth: People power progress. From diagnosing frictions in legacy-laden plants to scaling cobot collaborations under CHIPS incentives, frontline leaders, fortified by training, development, and tools, dissolve barriers that once cost billions in delays and churn. As projections warn of 1.9 million unfilled roles amid 3.8 million openings by 2033, this isn’t mere adaptation, it’s reinvention, blending AI analytics with human judgment for resilient, sustainable factories.

Looking ahead, trends like gen AI’s 55% adoption and reshoring’s momentum signal opportunity: Firms prioritizing leadership will capture the 19.54% CAGR, turning hurdles into ROI engines.

Yet, success demands boldness—upskilling 54% of the workforce, fostering a workplace environment of trust, and measuring beyond metrics to morale.

For U.S. manufacturers charting this course, shop-floor resources like DPS, our Digital Production System offer grounded pathways to frontline empowerment, rooted in real transformations that align people and tech for tomorrow’s edge.

About POWERS: Your Partner in Frontline Leadership Excellence

At POWERS, we help manufacturing leaders bridge the skills and behaviors gap and conquer technology adoption friction through targeted frontline leadership development. With decades of results-producing expertise, we address the behavioral and technical hurdles that slow digital transformation, equipping your supervisors and team leads, the guardians of 80% of shop-floor operations, with the skills and behaviors to foster seamless people-tech integration.

Our proprietary and proven methods, and DPS, our Digital Production System, provide the practical tools and training to turn reluctance into rapid adoption. We don’t just train; we transform your frontline into resilient accelerators, delivering measurable gains in productivity and profitability. Whether you’re tackling legacy system silos, upskilling for AI analytics, or prepping for reshoring demands, our tailored programs unlock the human potential that drives sustainable results.

Take the Next Step to Equip Your Frontline

- Speak to an Expert: Call +1 678-971-4711 to discuss how frontline leadership development and DPS can close your skills gap and streamline tech adoption.

- Email Us: Reach out to info@thepowerscompany.com for personalized insights on reducing friction in your operations.

- Request an Assessment: Visit our online contact form to schedule an assessment with our expert consultants, identifying quick wins to equip your leaders and boost performance.