Downloadables

Quick-win tools and resources for manufacturing leaders

Looking to boost productivity, streamline your operations, or improve leadership habits on the shop floor? Download our free resources developed by the experts at POWERS to help supervisors and managers solve real-world manufacturing challenges fast.

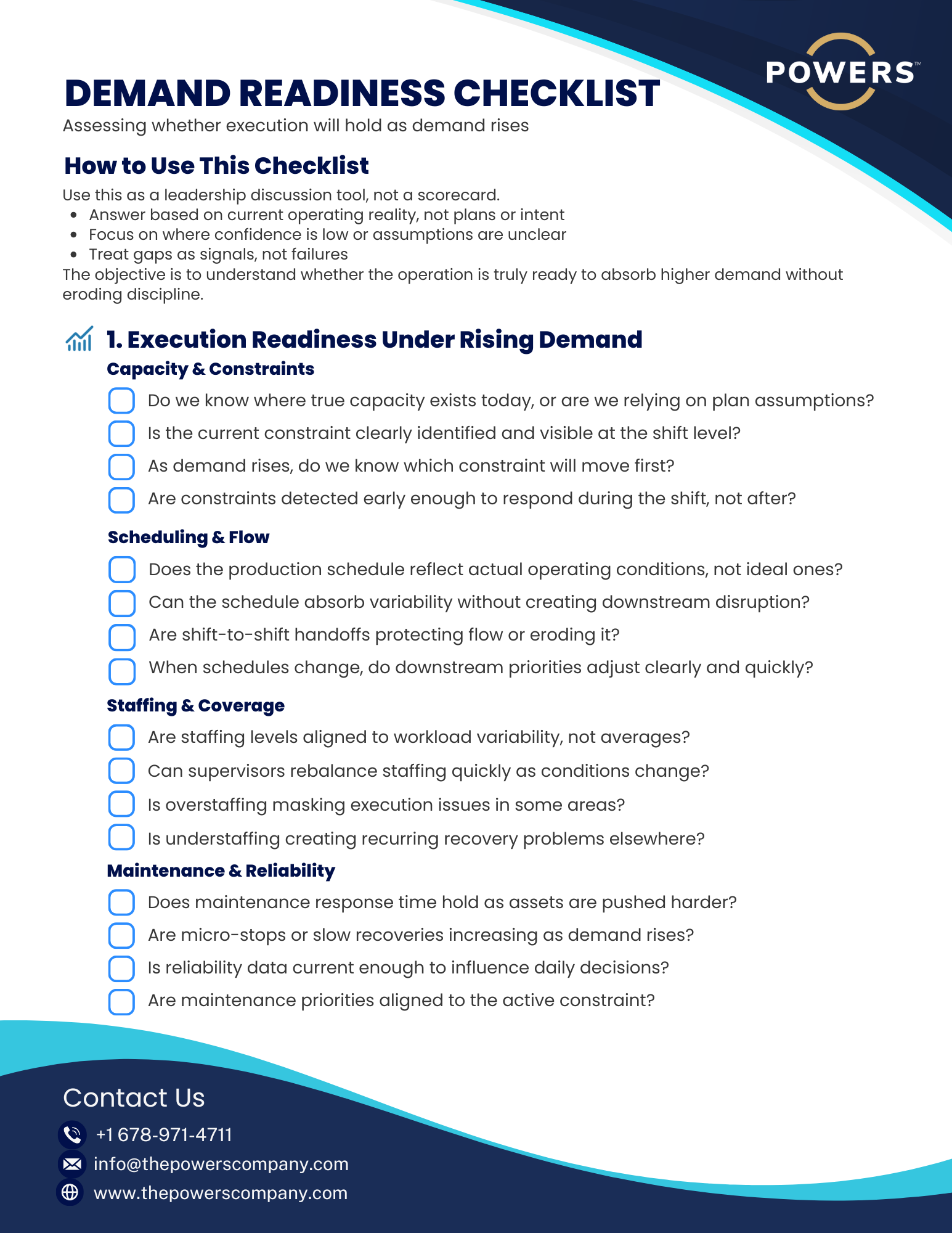

Demand Readiness Checklist

The Demand Readiness Checklist helps leaders quickly assess whether their operation can absorb rising demand without breaking execution discipline. It focuses on capacity, constraints, leadership routines, and the metrics that reveal risk before performance slips.

Operational Reset Checklist

The Operational Reset Checklist is a quick diagnostic for manufacturers to assess and realign performance gaps. It covers six critical pillars, from leadership discipline to production flow, to help anchor your operational reset.

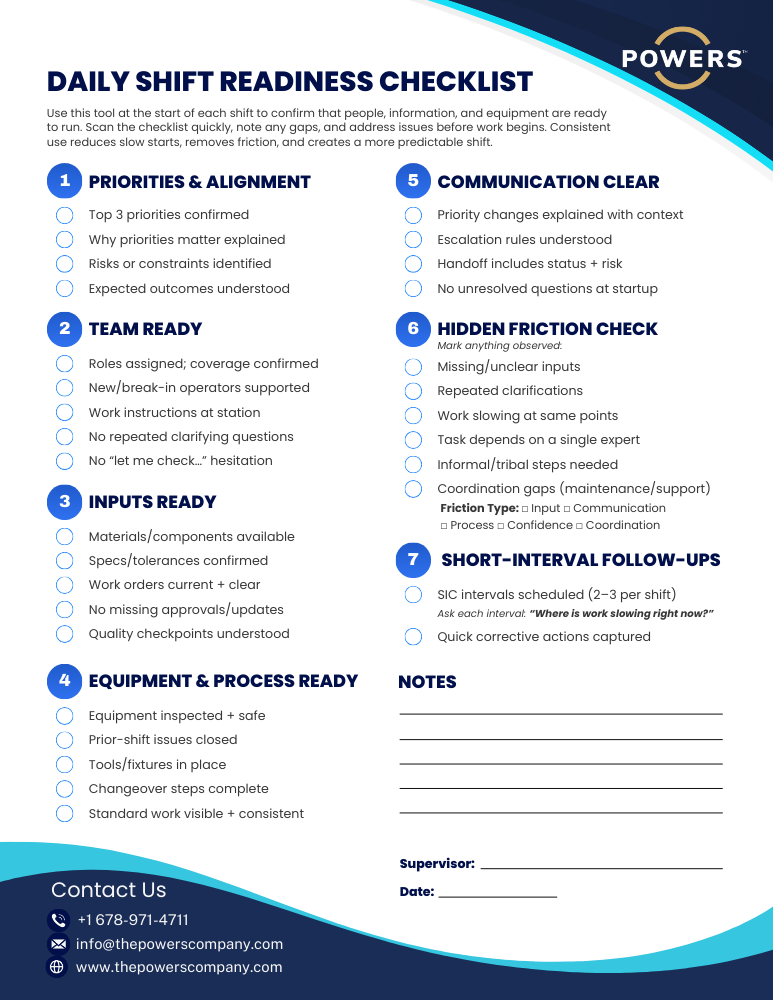

Daily Shift Readiness Checklist

Use this tool at the start of each shift to confirm that people, information, and equipment are ready to run. Scan the checklist quickly, note any gaps, and address issues before work begins. Consistent use reduces slow starts, removes friction, and creates a more predictable shift.

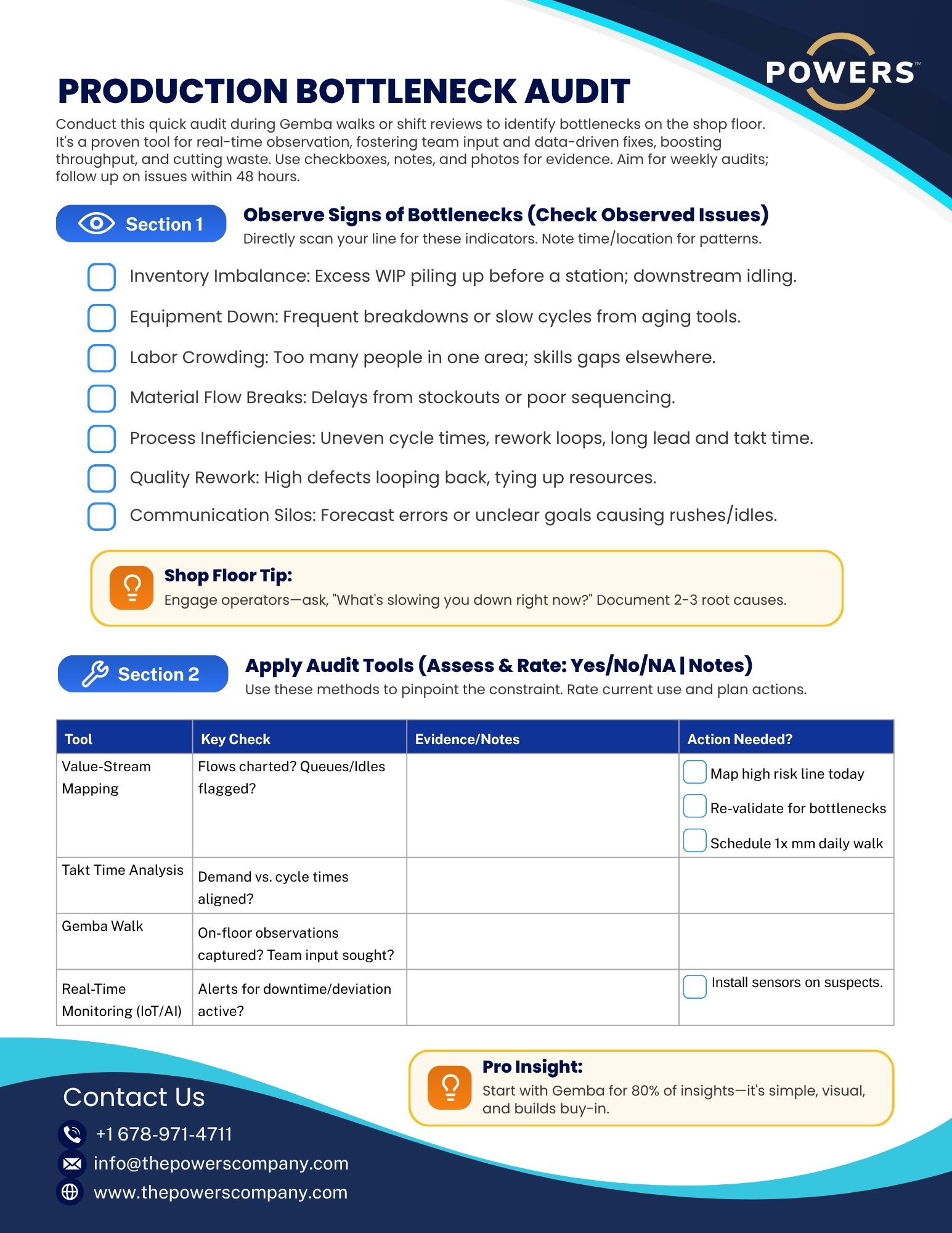

Production Bottleneck Audit

Conduct this quick audit during Gemba walks or shift reviews to identify bottlenecks on the shop floor. It's a proven tool for real-time observation, fostering team input and data-driven fixes, boosting throughput, and cutting waste. Use checkboxes, notes, and photos for evidence. Aim for weekly audits; follow up on issues within 48 hours.

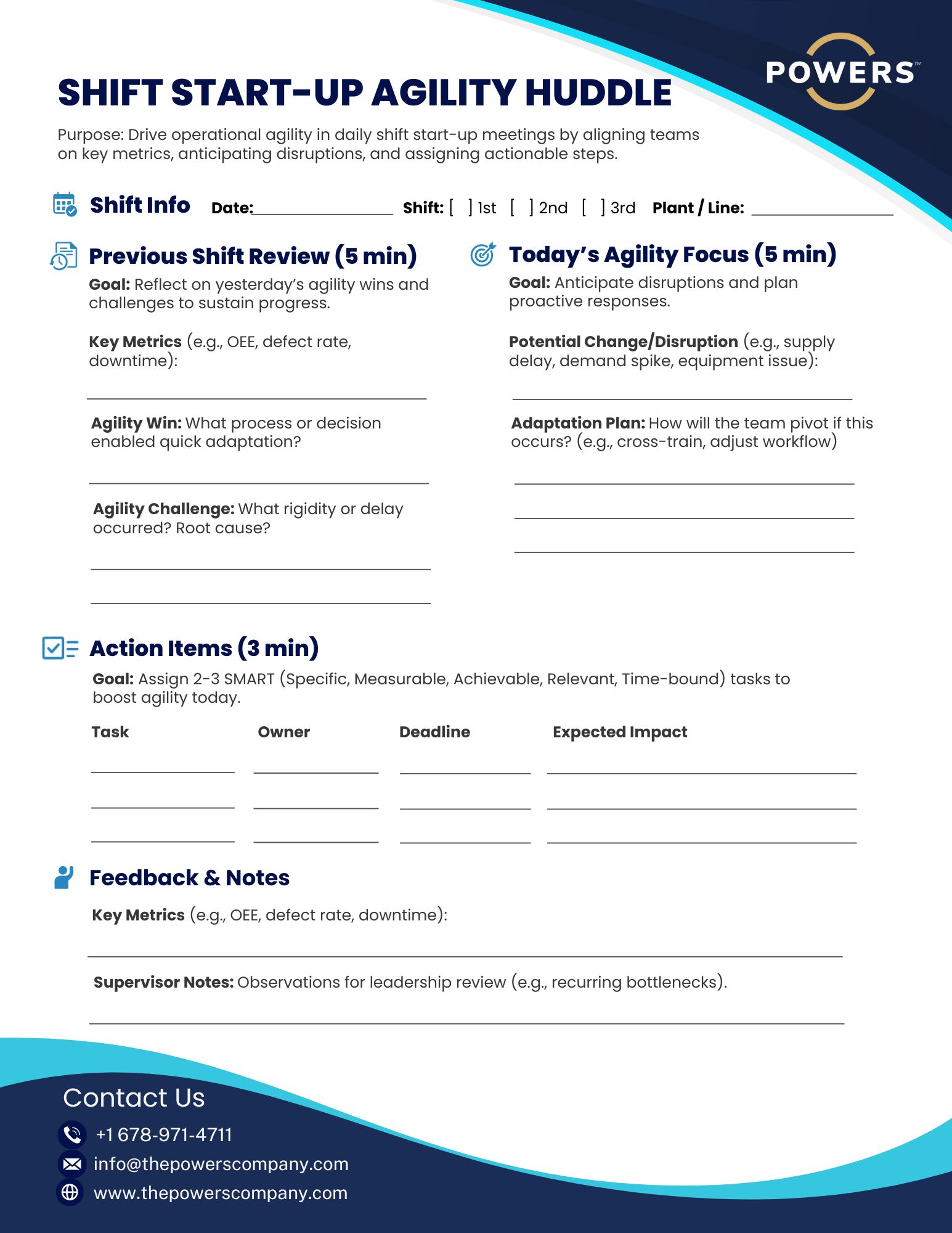

Shift Startup Agility Huddle

A practical guide to running daily shift huddles that build agility on the shop floor. This downloadable helps teams align on key metrics, review agility wins and challenges, anticipate disruptions, and assign actionable tasks that drive faster, smarter responses in production.

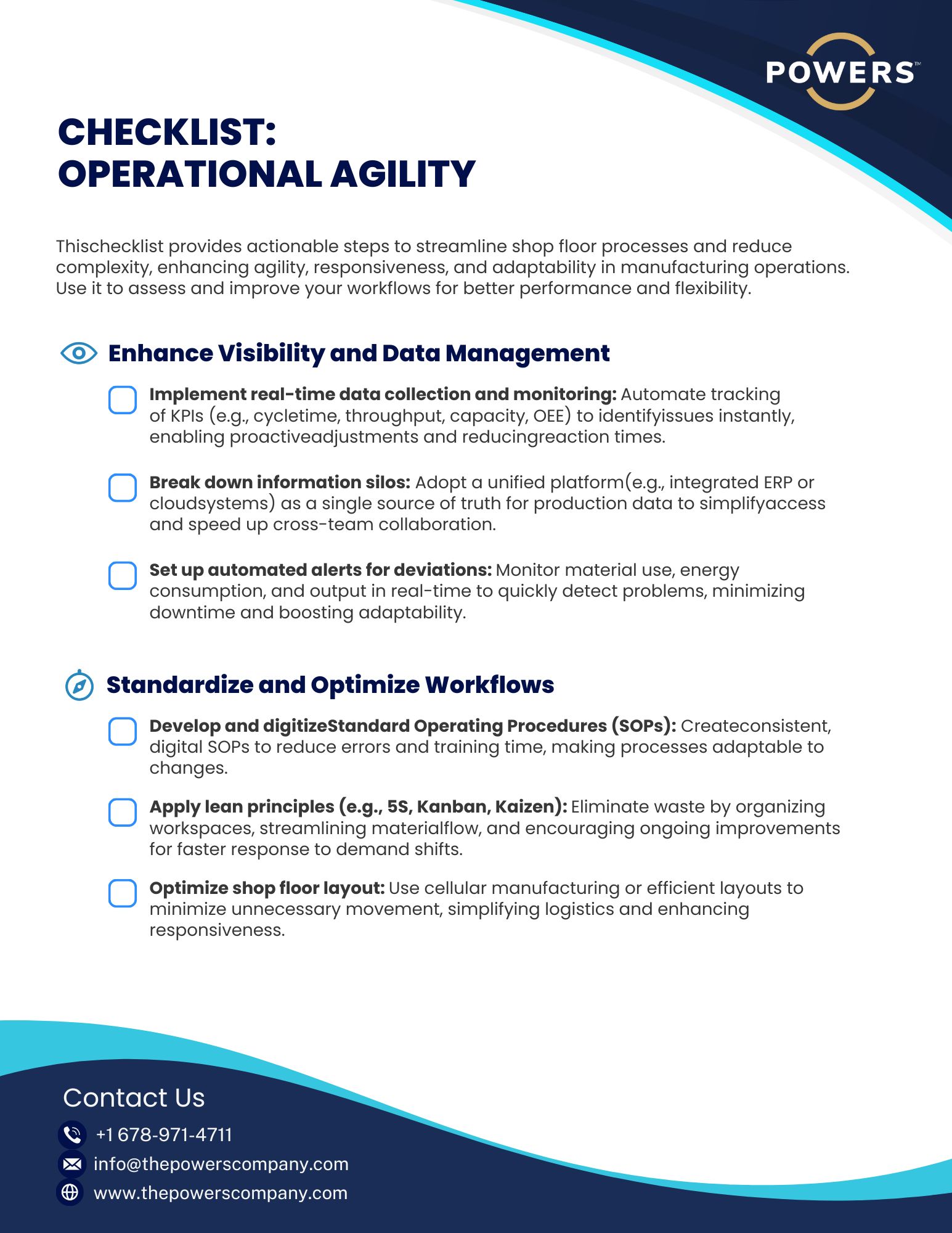

Increasing Operational Agility Checklist

A practical tool to help manufacturers streamline processes, reduce complexity, and improve responsiveness on the shop floor. This checklist covers visibility, workflow optimization, automation, and workforce adaptability, giving teams clear steps to strengthen agility and stay competitive.

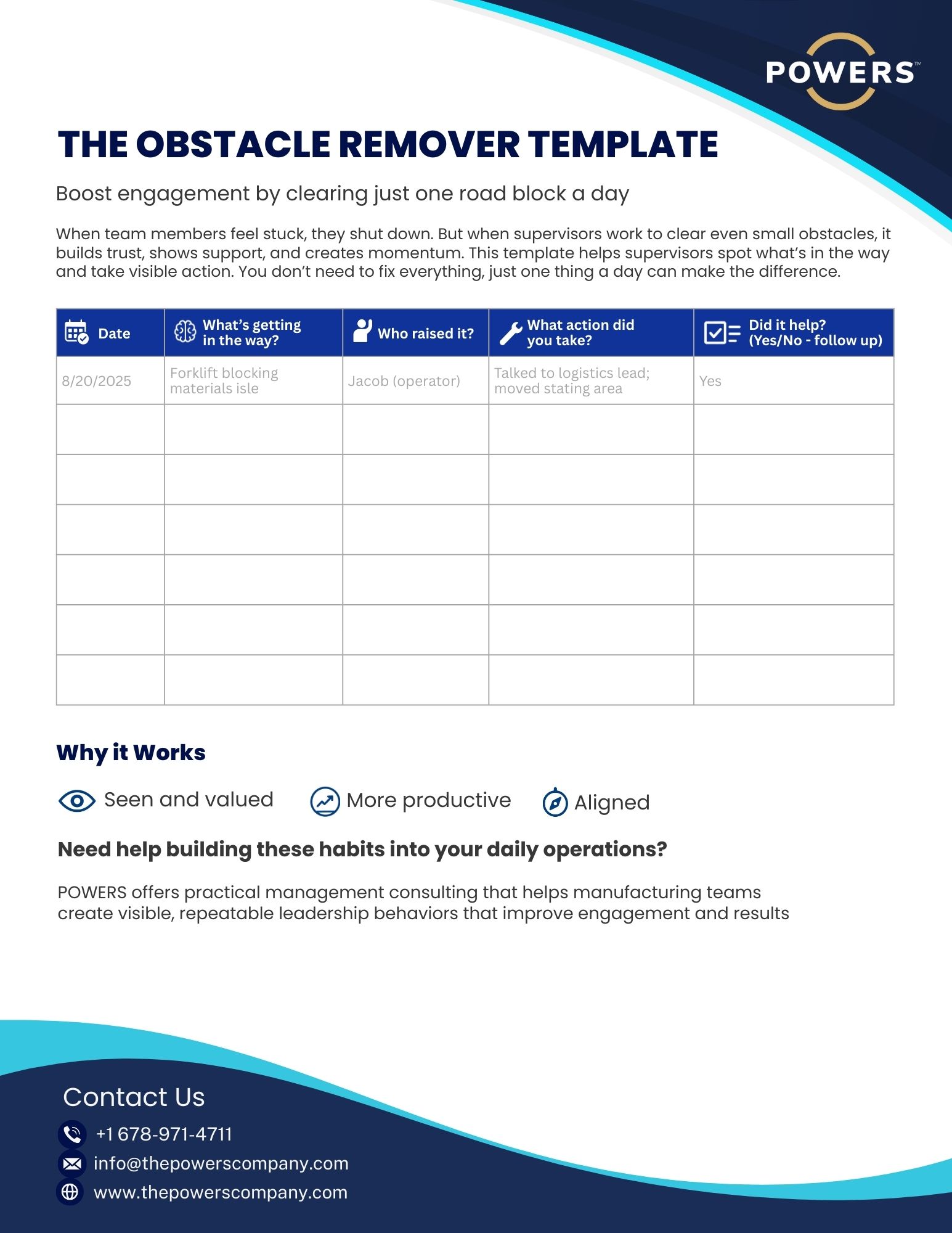

The Obstacle Remover Template

Boost engagement by clearing just one roadblock a day. This simple 5-day log helps supervisors track obstacles, take visible action, and show support where it matters most. By addressing even small barriers, leaders build trust, strengthen alignment, and create a more engaged, productive team.

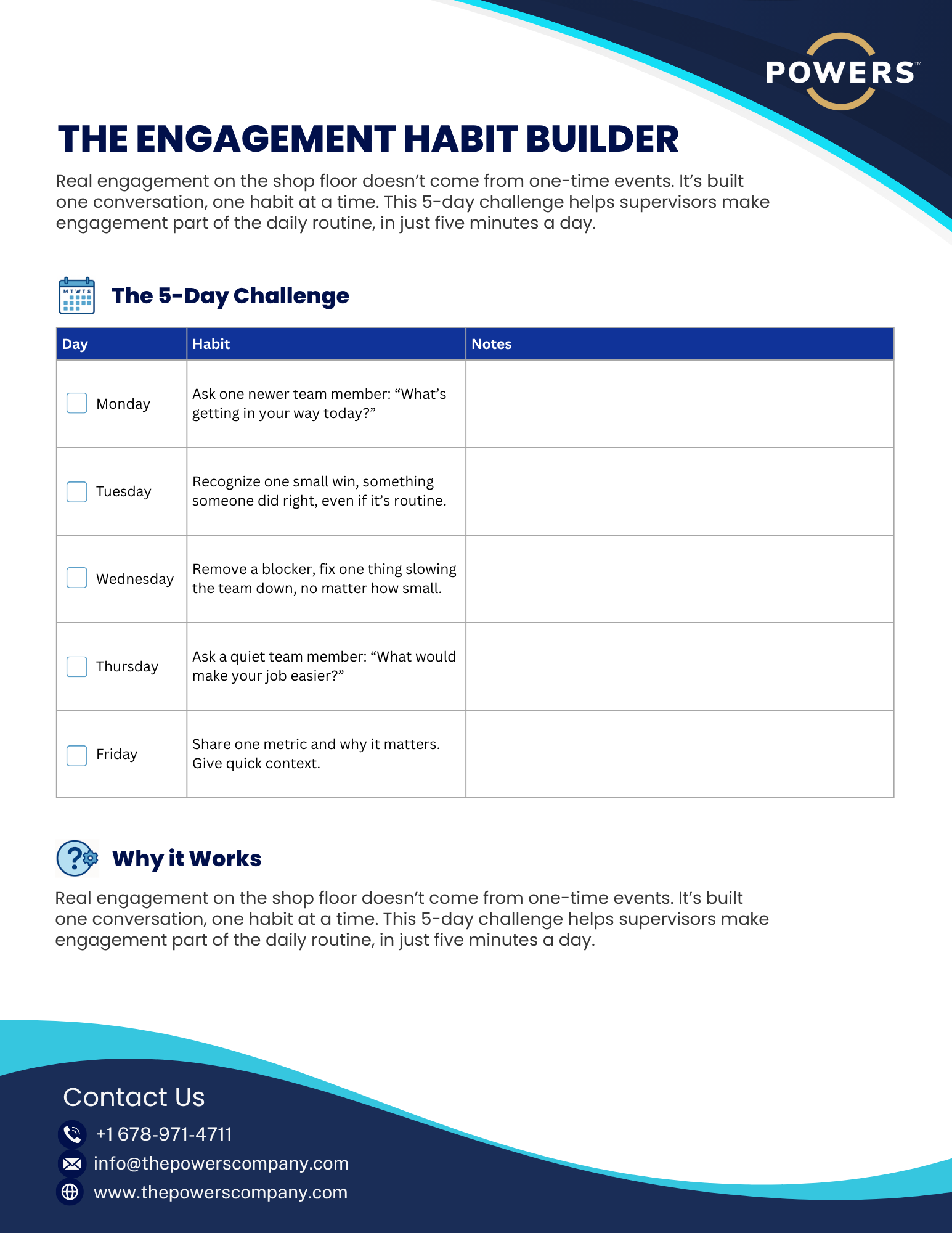

The Engagement Habit Builder

A simple, one-page tool to help frontline leaders build real engagement in just 5 minutes a day. Includes a 5-day challenge with daily habits, checkboxes, and space for notes. Perfect for supervisors looking to strengthen team communication without adding more to their plate.

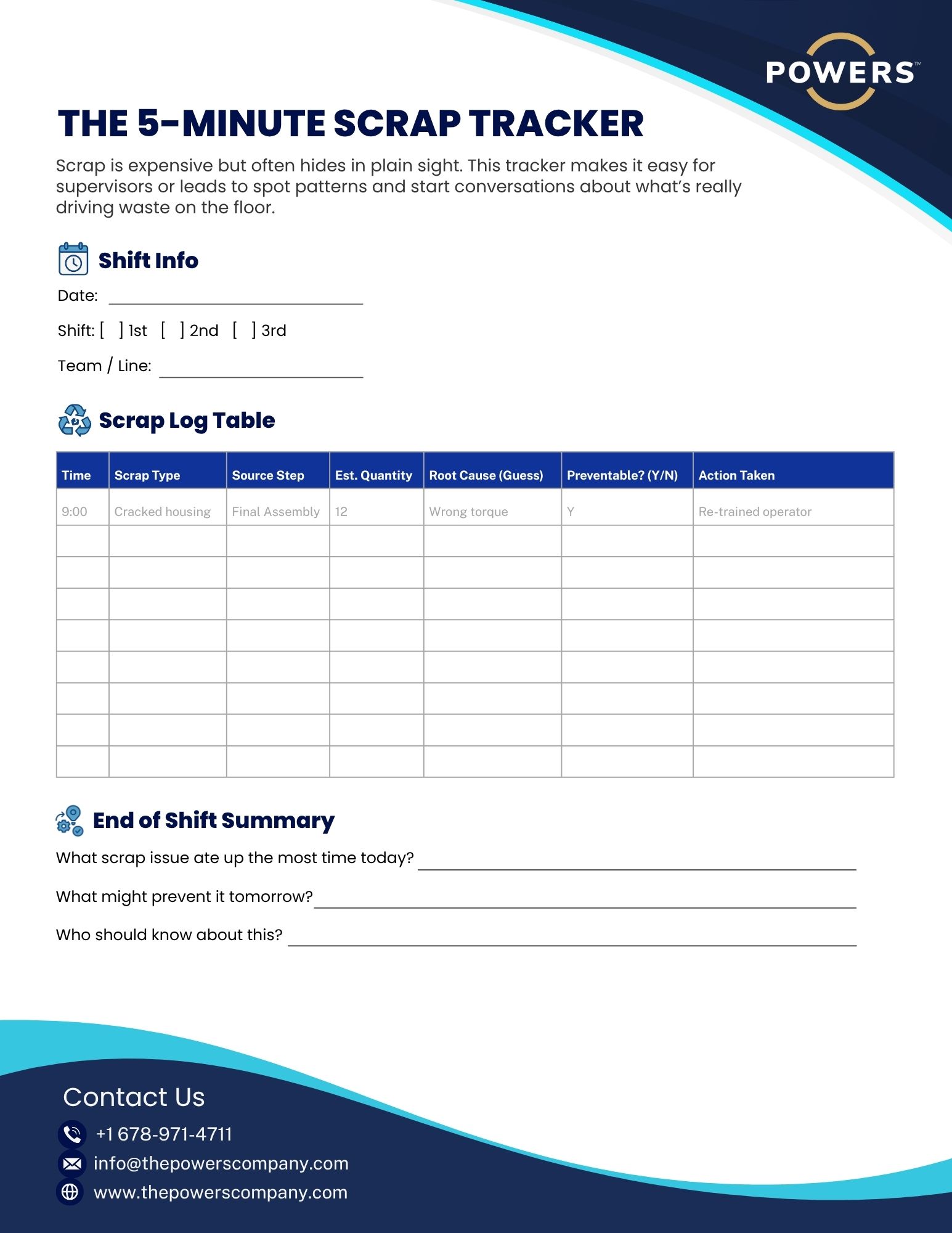

5-Minute Scrap Tracker

This printable worksheet helps frontline teams log scrap and rework in real time. Capture what’s being scrapped, where it’s happening, and why, so you can spot patterns, reduce waste, and lower costs without extra complexity.

The One-Day Waste Walk Guide

This practical guide helps manufacturing teams identify and eliminate costly inefficiencies on the shop floor in just 30–60 minutes. Includes a step-by-step walkthrough, a waste checklist, and a ready-to-use observation form to drive immediate cost-cutting action.

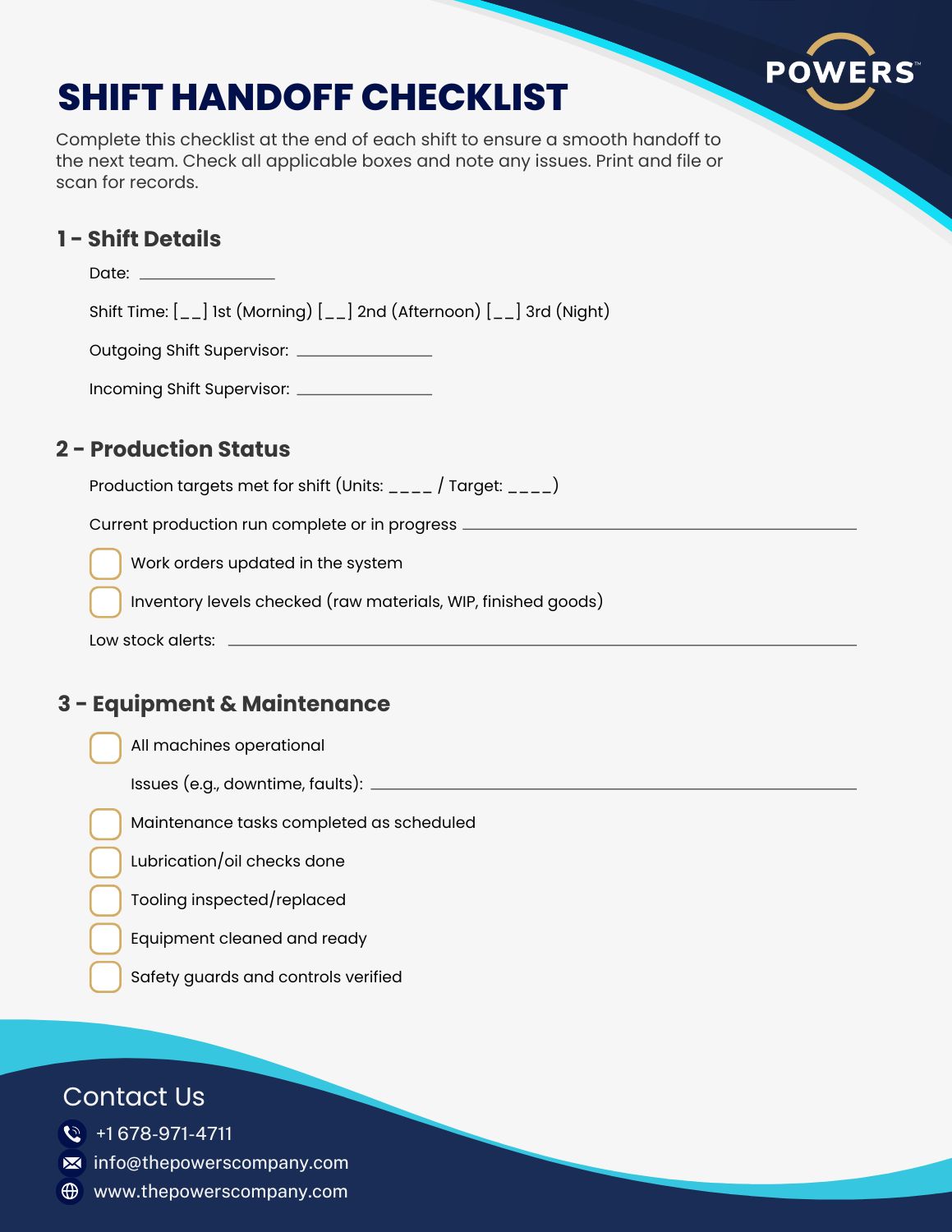

Shift Handoff Checklist

A simple checklist to improve shift transitions and maintain consistent resource flow. Use this tool to align on production status, flag open issues, and ensure smooth communication between teams. Designed to reduce handoff errors and avoid costly delays.

5 Root Cause Analysis Methods Every Manufacturing Leader Should Know

Quickly get to the bottom of recurring problems. This guide outlines five proven root cause analysis methods, like the 5 Whys and Fishbone Diagram that help manufacturing leaders identify issues faster, reduce downtime, and drive continuous improvement on the shop floor.

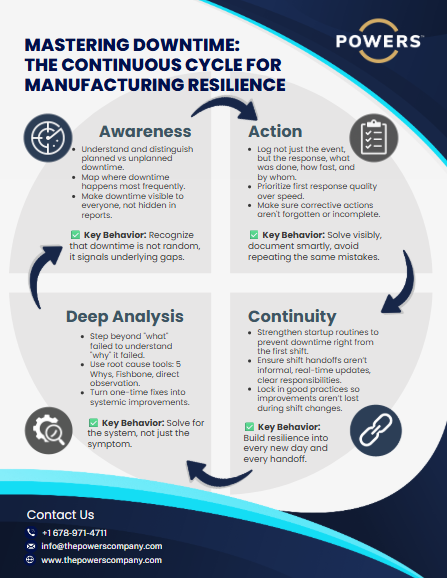

Mastering Downtime: The Continuous Cycle for Manufacturing Resilience

Turn unplanned downtime into a catalyst for improvement. This resource introduces a practical, repeatable cycle to help manufacturing leaders identify, respond to, and prevent downtime events building long-term operational resilience.

10 Habits of Highly Effective Frontline Leaders

Build habits that drive performance from the ground up. This one-pager outlines 10 daily behaviors that empower frontline leaders to boost accountability, improve communication, and keep operations running smoothly.

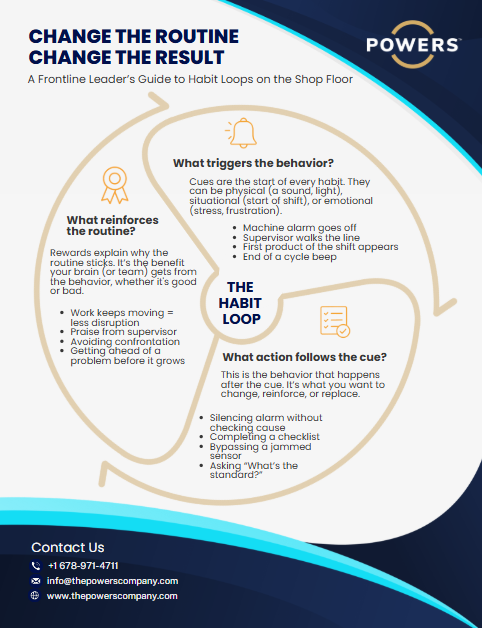

Habit Loop

Understand how habits form and how to change them. This simple visual breaks down the habit loop into three key parts: cue, routine, and reward. Use it to help your team reinforce productive behaviors on the shop floor.

Resource Flow Mapper

Spot bottlenecks before they slow you down. This visual template helps manufacturing teams map the flow of materials, information, and time so you can identify choke points, reduce delays, and streamline operations.